Bridge construction is one of the most complex and demanding sectors in the infrastructure industry. From large-span highway bridges and railway viaducts to urban overpasses and marine bridges, every project requires high safety standards, precise structural support, and reliable access systems. Scaffolding and formwork play a critical role throughout the entire bridge construction process, supporting concrete structures, enabling safe work at height, and ensuring construction efficiency and quality.

Structural Support for Bridge Foundations and Piers

During the early stages of bridge construction, strong and stable support systems are essential for building foundations, piers, and columns. Steel props, screw jacks, and heavy-duty formwork systems are widely used to support formwork during concrete pouring and curing. These components provide high load-bearing capacity and excellent stability, even under heavy concrete pressure and complex site conditions.

Ringlock scaffolding systems are particularly suitable for bridge pier construction due to their modular design and strong structural integrity. They can be assembled into various configurations to adapt to different pier shapes and heights, ensuring precise alignment and consistent support. Adjustable screw jacks allow fine height adjustment, helping contractors achieve accurate elevations and reduce structural deviations.

Safe Access for High-Level and Complex Structures

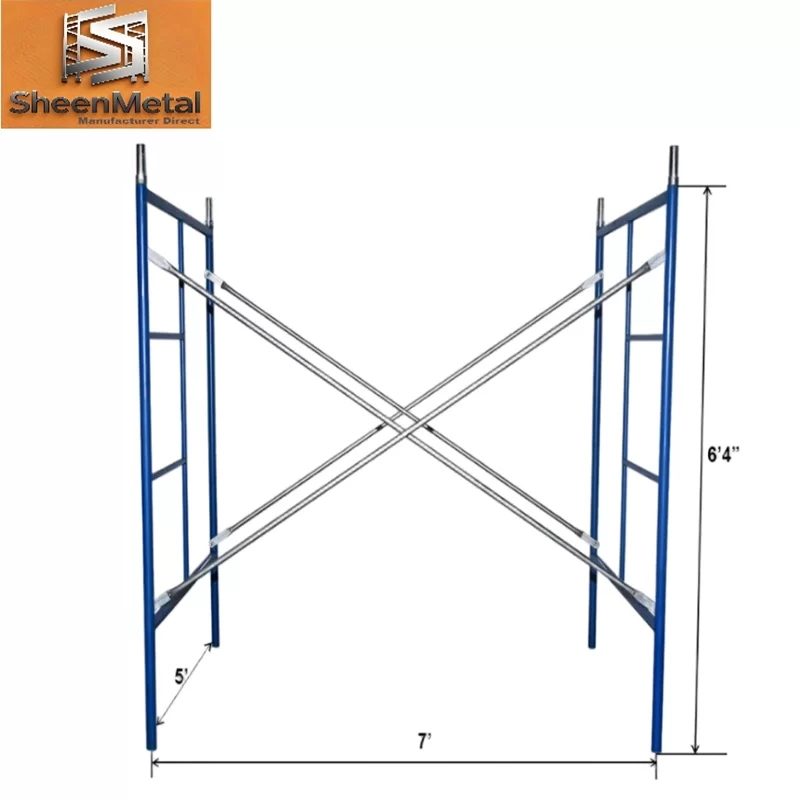

Bridge construction often involves working at significant heights and over water, roads, or railways. Reliable access scaffolding systems are crucial to protect workers and ensure smooth construction progress. Frame scaffolding, ringlock scaffolding, and tube-and-coupler systems are commonly used to create safe working platforms around piers, beams, and decks.

Ringlock scaffolding is widely favored for bridge projects because of its high load capacity, quick assembly, and excellent adaptability. It allows the creation of multi-level platforms, stair access, and guardrail systems that meet strict safety regulations. For irregular bridge structures or special construction zones, scaffolding tube and coupler systems offer maximum flexibility, enabling customized layouts that follow complex geometries.

Efficient Support for Bridge Deck and Beam Construction

The construction of bridge decks and beams requires precise formwork and stable temporary structures. Steel props, formwork panels, and scaffolding systems work together to support the formwork during concrete pouring. High-quality scaffolding boards and planks provide safe and stable walking surfaces for workers installing reinforcement, formwork, and post-tensioning systems.

In long-span bridge projects, scaffolding systems must support heavy loads while maintaining dimensional accuracy. Modular scaffolding systems allow engineers to design efficient shoring towers and falsework structures that distribute loads evenly and minimize deformation. This improves concrete quality, reduces rework, and shortens construction cycles.

Adaptability to Marine and Overwater Environments

Many bridge projects are built over rivers, lakes, or coastal areas, where environmental conditions present additional challenges. Scaffolding and formwork systems used in these environments must offer strong corrosion resistance and structural reliability. Galvanized steel scaffolding components and formwork accessories are commonly used to withstand moisture, salt spray, and harsh weather conditions.

Scaffolding caster wheels and mobile scaffold systems are sometimes used on temporary platforms or completed deck sections to improve mobility during installation and inspection work. These solutions enhance flexibility while maintaining safety, especially in confined or changing work zones.

Improved Construction Efficiency and Project Control

Time control is critical in bridge construction, especially for large infrastructure projects with strict deadlines. Modular scaffolding and formwork systems help improve construction efficiency by reducing assembly time and simplifying logistics. Standardized components are easy to transport, store, and reuse across different bridge sections, lowering overall project costs.

Quick-lock systems such as ringlock scaffolding reduce labor intensity and installation errors, improving on-site productivity. The ability to dismantle and relocate scaffolding systems efficiently also helps contractors manage phased construction and reduce downtime between stages.

Enhanced Safety and Compliance with International Standards

Safety is a top priority in bridge construction projects. Scaffolding and formwork systems must comply with international safety standards to protect workers and meet regulatory requirements. High-quality systems are designed with secure connections, anti-slip platforms, and stable load paths to minimize risks during installation and operation.

Properly designed scaffolding solutions provide secure guardrails, toe boards, and access ladders or stairways, creating a safe working environment even in high-risk areas. Using certified components and standardized systems helps contractors pass inspections and maintain a strong safety record throughout the project lifecycle.

Cost-Effective and Sustainable Construction Solutions

Modern bridge construction emphasizes not only safety and efficiency but also sustainability. Reusable scaffolding and formwork systems significantly reduce material waste compared to traditional timber structures. Steel scaffolding components offer long service life and can be reused across multiple projects, improving return on investment.

Efficient scaffolding design also reduces material consumption by optimizing load distribution and minimizing unnecessary components. This contributes to lower project costs and supports environmentally responsible construction practices.

Supporting Complex Bridge Designs

As bridge designs become more innovative and architecturally complex, scaffolding and formwork systems must adapt accordingly. Curved decks, inclined pylons, and irregular cross-sections require flexible and customizable support solutions. Tube and coupler scaffolding systems, combined with modular formwork panels, allow engineers to create tailored support structures that match complex geometries.

This adaptability is especially important for landmark bridges and urban infrastructure projects where aesthetic design and structural performance are equally important.

Conclusion

Scaffolding and formwork systems are essential components in modern bridge construction, providing structural support, safe access, and construction efficiency across all project stages. From foundation work and pier construction to deck pouring and finishing, reliable systems such as steel props, ringlock scaffolding, frame scaffolding, and formwork solutions help ensure project safety, quality, and on-time delivery.

By choosing high-quality scaffolding and formwork products designed for bridge construction, contractors can meet demanding engineering requirements, reduce risks, and achieve long-term project success in complex infrastructure environments.

As global infrastructure development continues to accelerate, the demand for safe, efficient, and adaptable construction solutions has never been higher.

Interior decoration and renovation projects are experiencing strong growth worldwide, driven by urban development, commercial expansion, and increasing demand for high-quality indoor spaces.

The global shipbuilding industry is undergoing continuous transformation, driven by higher safety standards, increasing vessel complexity, and growing pressure to improve production efficiency.