Scaffolding Boards and Planks offer a combination of safety, durability, and versatility, making them vital for scaffolding platforms. One of the primary advantages is the stable and secure walking surface they provide, reducing the risk of slips, trips, or falls while working at height. Boards and planks are manufactured to strict tolerances, ensuring straightness, flatness, and strength under load.

Load-bearing capacity is a key feature. High-quality boards can support workers, tools, and materials simultaneously without excessive bending or deformation. Timber planks are often reinforced or graded to ensure structural integrity, while steel and aluminum planks provide additional strength, especially for heavy-duty applications.

Another benefit is versatility. Scaffolding boards can be used in combination with a wide range of scaffold systems, including frame scaffolding, Ringlock scaffolding, Cuplock scaffolding, and mobile scaffolds. They are available in various lengths, widths, and thicknesses, allowing customization for specific project requirements.

Durability and resistance to environmental factors are also crucial. Timber boards are treated to resist moisture, decay, and insect damage, while steel and aluminum planks are corrosion-resistant and suitable for both indoor and outdoor use. Lightweight options improve handling and installation efficiency without compromising strength.

Overall, Scaffolding Boards and Planks combine strength, safety, adaptability, and durability, making them an essential component for engineers, contractors, and site managers seeking reliable working platforms for construction, maintenance, or industrial projects.

Scaffolding Boards and Planks are manufactured according to international safety and quality standards. Typical technical parameters include:

Material: Timber (treated hardwood or softwood), steel, or aluminum

Length: 2.0 m, 2.5 m, 3.0 m, or custom sizes

Width: 200–300 mm (timber), 200–300 mm (metal)

Thickness: 38 mm (timber), 1.5–2.0 mm (steel/aluminum)

Load Capacity: 200–500 kg per board depending on material and support span

Surface: Anti-slip or grooved finish for safety

Treatment: Pressure-treated timber for moisture and insect resistance; galvanized or anodized coating for metal boards

Compatibility: Suitable for frame scaffolding, Ringlock scaffolding, mobile scaffolds, and other supported systems

Application: Provides walking surface for personnel, tools, and materials on scaffolding platforms

Timber boards are graded to ensure uniform strength, while steel and aluminum planks are designed for high-strength, heavy-duty applications. Boards can be supported directly on scaffolding ledgers or on adjustable U Head Jacks and base plates for leveling.

Regular inspection is essential to check for cracks, deformation, corrosion, or wear. Correct installation and proper support ensure safety, durability, and optimal load distribution across the scaffold platform.

Scaffolding Boards and Planks are critical components of safe and stable scaffolding platforms. They serve as the working surface for personnel and as a support for tools and materials during construction, maintenance, or industrial tasks. The right choice of material, size, and load capacity ensures operational safety and productivity.

Timber boards are widely used due to their natural flexibility, load-bearing capability, and cost-effectiveness. Treated hardwood is preferred for heavy-duty applications, while softwood may be suitable for lighter tasks. Steel and aluminum planks are used in industrial or high-load scenarios, offering excellent strength, corrosion resistance, and longer service life.

Proper installation involves placing the boards across scaffolding ledgers or planks supports to create a flat, level surface. Anti-slip treatments, grooved surfaces, or coatings further enhance worker safety. The boards must be supported at the ends and mid-span where required to prevent excessive deflection or bending under load.

Compared with temporary platforms without planks, scaffolding boards improve stability, safety, and efficiency, reducing accidents and improving workflow. They are compatible with various scaffolding systems, including frame scaffolds, Ringlock, Cuplock, and mobile scaffolds.

Routine maintenance, including inspection for cracks, warping, corrosion, or surface wear, is essential to prolong lifespan and ensure safety. Boards and planks can be reused across multiple projects, offering cost-effective, reliable, and sustainable solutions for construction and industrial operations.

Visual content is essential for demonstrating the structure, installation, and applications of scaffolding boards and planks. High-quality images help engineers, contractors, and site supervisors understand installation methods, safety features, and compatibility.

Common image types include:

Product Overview: Individual timber, steel, and aluminum boards showing thickness, width, and surface finish

Detail Images: Close-ups of anti-slip surfaces, grooved designs, edges, and coatings

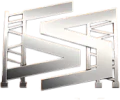

Installation Examples: Boards laid across ledgers on frame scaffolding, Ringlock scaffolding, or mobile scaffold platforms

On-Site Applications: Platforms supporting workers, tools, and materials in construction, industrial maintenance, and high-rise projects

Load Demonstration: Images showing weight distribution and structural stability under load

Safety Features: Anti-slip coatings, properly supported ends, and mid-span support demonstration

These images are commonly used in catalogs, technical manuals, online product listings, and training guides. They provide practical guidance for safe installation, highlight load-bearing capabilities, and demonstrate versatility in different scaffolding configurations.

Combining detailed specifications with high-quality visuals ensures that engineers, contractors, and site managers can confidently select Scaffolding Boards and Planks for safe, durable, and reliable working platforms across all construction and industrial projects.