Drop Forged Couplers are engineered to deliver maximum strength, safety, and efficiency in reinforced concrete construction. One of their primary advantages is the high structural integrity achieved through the drop forging process. Drop forging aligns the steel’s grain structure, enhancing the coupler’s tensile and shear strength compared to standard cast or welded couplers.

These couplers provide mechanical continuity for steel reinforcement, eliminating the need for extended lap splicing, which reduces material usage and prevents congestion in densely reinforced areas. By connecting rebar end-to-end, Drop Forged Couplers ensure uniform load transfer and reliable structural performance.

Ease of installation is another key benefit. They can be quickly attached to threaded or plain rebar ends, depending on the design, allowing for faster on-site assembly and improved construction timelines. Their precision-engineered design ensures compatibility with a wide range of rebar diameters and grades.

Durability and corrosion resistance are also significant advantages. Drop Forged Couplers are typically made from high-strength alloy steel and can be treated with galvanization or anti-corrosion coatings for long-lasting performance in harsh environmental conditions. Reusable molds and precise manufacturing ensure consistent quality, making them cost-effective for multiple projects.

Overall, Drop Forged Couplers combine strength, reliability, efficiency, and long-term durability, making them a preferred solution for engineers, contractors, and construction professionals seeking high-quality mechanical splicing systems in reinforced concrete projects.

Drop Forged Couplers are manufactured to stringent standards to ensure performance, safety, and compliance with international construction codes. Typical technical parameters include:

Material: High-strength alloy steel, drop forged

Type: Threaded, compression, or wedge couplers

Diameter Compatibility: Rebar sizes from 12 mm to 50 mm (custom sizes available)

Load Capacity: Equal to or exceeding the yield strength of connected rebars

Surface Treatment: Hot-dip galvanized, painted, or epoxy-coated for corrosion resistance

Compliance Standards: ISO 15835, BS 8666, ASTM A1034, or equivalent

Application: Mechanical splicing in reinforced concrete, precast elements, high-rise and industrial structures

The drop forging process enhances the coupler’s mechanical properties, resulting in superior tensile strength, fatigue resistance, and dimensional accuracy. Threaded couplers provide secure torque-based connections, while wedge or compression types allow fast assembly without specialized tools.

Installation requires proper alignment, torque application (for threaded types), and adherence to manufacturer guidelines. Correct installation ensures that the coupler can transfer loads effectively, maintaining structural integrity and meeting design specifications.

Regular inspection before and during concrete placement ensures safety and performance. Drop Forged Couplers are suitable for high-rise structures, bridges, precast panels, and heavily reinforced concrete elements, providing reliable mechanical connections under demanding conditions.

Drop Forged Couplers are a key innovation in reinforced concrete construction, providing mechanical continuity for steel reinforcement without the need for extended lap splicing. Their primary function is to transfer tensile and compressive loads between connected rebars efficiently and safely.

The couplers operate on the principle of mechanical interlock or threaded connection. Threaded couplers require precision threading of rebar ends and torque-controlled assembly, while wedge or compression couplers grip the bar using mechanical force. Drop forging ensures consistent material properties and eliminates internal defects that could reduce load-bearing capacity.

Compared to traditional lap splices or cast/welded couplers, Drop Forged Couplers offer several advantages: higher tensile strength, reduced steel usage, faster assembly, and improved concrete quality. They are particularly valuable in high-rise buildings, bridges, heavy infrastructure, and precast concrete projects, where space and congestion are critical concerns.

Proper installation involves selecting the appropriate coupler type for the rebar size and grade, aligning the bars correctly, and ensuring secure connection according to engineering specifications. With correct usage, Drop Forged Couplers provide a safe, durable, and cost-effective mechanical splicing solution, improving structural integrity and construction efficiency.

Additionally, their corrosion-resistant finishes and high-quality steel construction ensure that they maintain performance even in harsh environmental conditions. They are reusable across multiple projects, offering long-term cost benefits.

Visual presentation is essential for demonstrating the structure, installation, and practical application of Drop Forged Couplers. Clear images help engineers, contractors, and site supervisors understand installation techniques, compatibility, and structural benefits.

Common image types include:

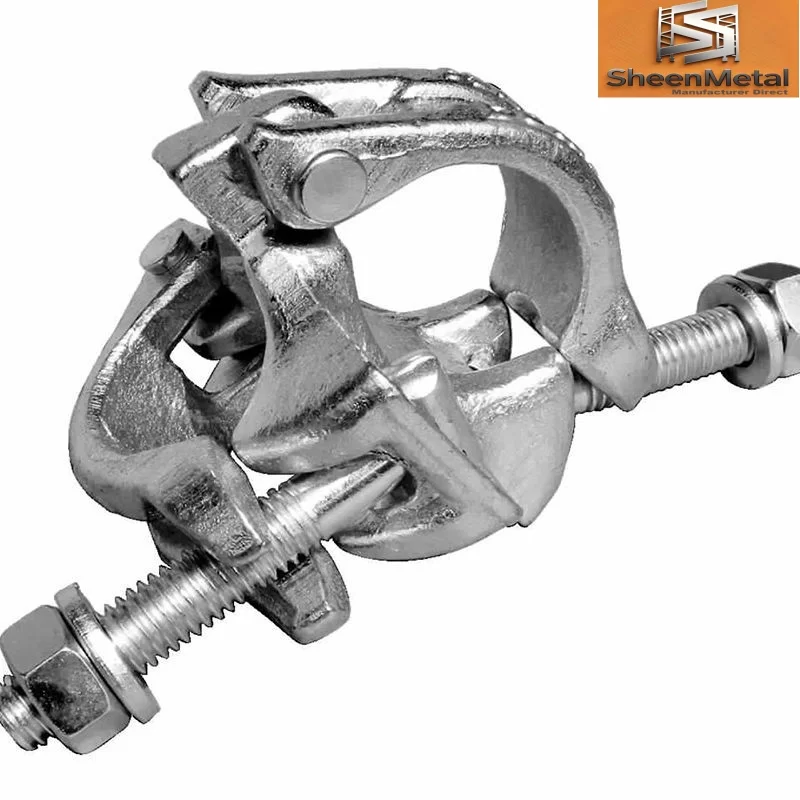

Product Overview: Individual Drop Forged Couplers showing their forged body, threads, and mechanical design.

Detail Images: Close-ups of threads, grooves, forged grain structure, and corrosion-resistant surfaces.

Installation Examples: Couplers connecting rebar in vertical and horizontal applications, showing precise alignment and torque application.

On-Site Applications: Photos of couplers used in high-rise buildings, bridges, precast panels, and industrial concrete structures.

Embedded Applications: Images showing couplers embedded during casting to form seamless connections.

Installation Process: Step-by-step visuals illustrating alignment, connection, torque application (for threaded types), and verification of secure load transfer.

These images are widely used in catalogs, technical manuals, online product pages, and construction training guides. They provide practical guidance for safe installation, highlight the coupler’s strength and durability, and demonstrate versatility in different reinforced concrete projects.

By combining detailed technical specifications with high-quality visuals, engineers and contractors can confidently select Drop Forged Couplers as a reliable, strong, and efficient solution for mechanical splicing in reinforced concrete structures.