The Push-Pull Prop stands out for its dual-function capability, allowing both pushing and pulling forces to be applied with high precision. Unlike conventional props that only provide vertical support, Push-Pull Props are specifically engineered for horizontal and inclined adjustment, making them ideal for wall formwork alignment, tilt-up panels, precast concrete elements, and façade installation.

One of the most important selling points is its high adjustability and accuracy. The threaded adjustment mechanism enables millimeter-level positioning, ensuring that walls, columns, and panels can be aligned precisely before and during concrete pouring. This significantly improves construction accuracy and reduces rework.

Strength and safety are core advantages. Push-Pull Props are manufactured from high-grade structural steel, providing excellent load-bearing capacity under both compression and tension. Secure locking mechanisms and reinforced end plates ensure stable load transfer and reliable performance even under dynamic construction conditions.

Ease of installation further enhances productivity. Push-Pull Props can be quickly fixed to concrete slabs, formwork panels, or structural elements using anchor bolts or embedded plates. Their simple operation reduces labor time and minimizes the need for additional alignment tools.

In addition, Push-Pull Props are highly reusable and cost-effective. With durable surface treatments such as painted, powder-coated, or galvanized finishes, they offer long service life and resistance to corrosion. This makes them an ideal choice for contractors seeking efficient, safe, and economical formwork alignment solutions.

The Push-Pull Prop is designed and manufactured according to strict quality and safety standards to ensure reliable performance across a wide range of construction applications. Typical technical parameters include:

Material: High-strength carbon steel

Type: Adjustable push-pull steel prop

Surface Treatment: Painted, powder-coated, or hot-dip galvanized

Adjustment System: Heavy-duty threaded sleeve with locking nut

Working Length Range: Commonly from 1.6 m to 6.0 m (custom sizes available)

Load Capacity: Designed for both compression and tension loads (capacity varies by length and model)

End Connections: Swivel plates, eye plates, or fork heads

Installation Method: Anchored to concrete slab or structure with bolts or embedded anchors

The robust threaded adjustment system allows smooth and precise length changes, enabling fine alignment even after formwork panels are positioned. End fittings are designed to accommodate angular movement, ensuring flexibility during installation.

Push-Pull Props are compatible with most wall formwork systems, precast panels, steel frames, and concrete structures. Their modular design allows them to be integrated into various construction setups without complex modifications.

To ensure safe operation, Push-Pull Props should be installed according to engineering guidelines, with appropriate anchoring and spacing. Regular inspection and maintenance help maintain performance and extend service life in demanding construction environments.

Push-Pull Props play a crucial role in temporary alignment and stabilization systems in modern construction. Their primary function is to control the position of vertical or inclined elements by applying controlled pushing or pulling forces during installation and concrete curing.

The working principle of a Push-Pull Prop is based on mechanical adjustment through a threaded steel mechanism. By rotating the adjustment sleeve, operators can extend or retract the prop, applying force to move formwork panels or structural elements into precise alignment. Once positioned, the locking system holds the prop securely in place.

Compared with traditional bracing methods using timber or fixed steel supports, Push-Pull Props offer superior precision, safety, and efficiency. They eliminate the need for repeated dismantling and repositioning, reducing labor time and improving construction accuracy.

Push-Pull Props are widely used in applications such as wall formwork alignment, precast concrete panel installation, column positioning, tunnel linings, and façade construction. They are especially valuable in projects where tight tolerances and high-quality finishes are required.

Proper usage is essential for safety and performance. Push-Pull Props must be securely anchored at both ends, installed at appropriate angles, and used within specified load limits. With correct installation and maintenance, they significantly enhance construction quality, reduce on-site risks, and support efficient project delivery.

Visual presentation is essential for showcasing the structure and functionality of Push-Pull Props. Product and application images help customers clearly understand how the prop works and where it can be used effectively.

Typical image content includes:

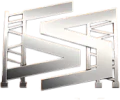

Product Overview Images: Showing the full Push-Pull Prop, including inner and outer tubes, threaded adjustment system, and end fittings.

Detail Images: Close-ups of the adjustment sleeve, locking nut, welds, and surface finish to highlight manufacturing quality.

Connection Details: Images showing different end types such as swivel plates, eye plates, or fork heads.

On-Site Applications: Photos of Push-Pull Props used for wall formwork alignment, precast panel installation, and column bracing.

Installation Examples: Step-by-step visuals demonstrating anchoring, adjustment, and final positioning.

These images are widely used in catalogs, product manuals, training materials, and online product pages. They provide practical guidance for installation and reinforce the product’s reliability and professional design.

Clear and detailed visuals help contractors and engineers quickly evaluate suitability, ensuring confident selection and safe use of Push-Pull Props in a wide range of construction projects.