The Tripod is an indispensable accessory in modern formwork and shoring systems, offering enhanced stability and safety during steel prop installation. One of its primary selling points is its ability to secure steel props in a vertical position, preventing movement or tipping before and during concrete pouring. This greatly reduces installation risks and improves overall site safety.

Another key advantage is its robust structural design. Made from high-quality steel, the Tripod provides strong lateral support, allowing steel props to remain firmly positioned even on uneven surfaces. The three-legged structure distributes loads evenly, ensuring excellent balance and resistance to accidental impacts on busy construction sites.

Ease of use is another major benefit. The Tripod can be quickly installed and adjusted by a single worker without special tools. Its simple locking mechanism allows fast opening, closing, and positioning around the steel prop, significantly reducing labor time and increasing installation efficiency.

The Tripod is also highly compatible and reusable. It works with most standard steel props used in slab and beam formwork systems. Durable surface treatments such as painted, powder-coated, or galvanized finishes protect the Tripod from corrosion, extending its service life even under harsh site conditions.

Overall, the Tripod enhances construction accuracy, safety, and productivity. By stabilizing steel props during critical installation stages, it helps contractors achieve safer working conditions, faster setup times, and more reliable formwork support systems.

The Tripod is designed according to standard construction requirements and manufactured with strict quality control to ensure consistent performance. Typical technical parameters include:

Material: High-strength carbon steel

Product Type: Steel prop support tripod

Surface Treatment: Painted, powder-coated, or hot-dip galvanized

Structure: Three-legged foldable design

Compatible Prop Size: Suitable for standard steel props (varies by model)

Height Adjustment: Adjustable clamping position

Weight: Optimized for stability and easy handling

Installation Method: Clamp-on or fixed support around steel prop

The foldable design allows the Tripod to be easily transported and stored when not in use. Once opened, the legs lock securely into position, providing stable lateral support. The clamping mechanism holds the steel prop firmly while still allowing fine vertical adjustment of the prop itself.

Tripods are commonly used in slab formwork systems, where accurate vertical alignment of steel props is critical. They are suitable for both indoor and outdoor construction projects and can be used on concrete, steel, or compacted ground surfaces.

For optimal performance, Tripods should be placed on stable ground and used according to recommended spacing and load guidelines. Regular inspection ensures safe operation and long-term durability in demanding construction environments.

In formwork and shoring systems, steel props provide vertical load-bearing support, while the Tripod serves as a stabilizing aid during installation. Its primary function is not to carry vertical loads but to maintain the prop’s position and alignment until the formwork system is fully assembled and secured.

The working principle of a Tripod is based on lateral stabilization. Once attached around the steel prop, the three legs create a wide base that resists tipping and movement. This allows workers to safely adjust prop height and position without the prop falling or shifting unexpectedly.

Compared to installing steel props without stabilization, using a Tripod significantly improves safety and efficiency. It reduces the risk of accidents, ensures more accurate alignment, and allows for faster installation by fewer workers.

Tripods are widely used in slab formwork, beam support systems, and temporary shoring applications in residential, commercial, and industrial construction projects. They are especially valuable in projects requiring high installation accuracy and strict safety standards.

Proper use is essential. Tripods should be securely fixed around the prop, fully opened, and placed on stable ground. Although they do not carry structural loads, their role in maintaining stability is critical for safe and efficient construction operations.

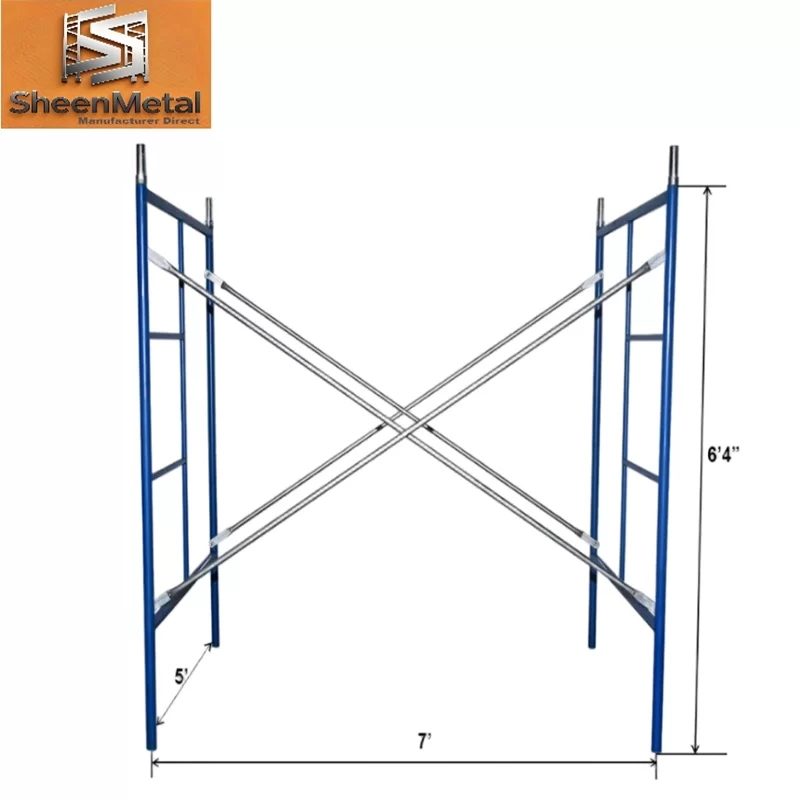

Product and application images play an important role in demonstrating the structure and practical use of the Tripod. Clear visuals help users understand how the Tripod supports steel props during installation and how it integrates into formwork systems.

Common image types include:

Product Overview Images: Showing the complete Tripod in open and folded positions.

Detail Images: Close-ups of clamps, hinges, locking mechanisms, and surface finish.

Compatibility Demonstrations: Images showing Tripods used with different types of steel props.

On-Site Application Photos: Tripods supporting steel props in slab and beam formwork systems.

Installation Process Images: Step-by-step visuals illustrating proper placement and adjustment.

These images are widely used in product catalogs, instruction manuals, safety training materials, and online product pages. They provide practical guidance and reinforce the reliability and quality of the Tripod.

By combining technical explanations with clear visuals, customers can quickly evaluate the Tripod’s function and benefits, ensuring correct selection and safe usage on construction sites.