The Forkhead is a crucial accessory in modern formwork systems, designed to enhance safety, stability, and ease of use when supporting horizontal structural elements. One of its key selling points is its secure clamping and load distribution capability. The forked design provides a stable cradle for beams and slabs, ensuring uniform load transfer from the supported element to the steel prop.

Another major advantage is its high-quality steel construction, which delivers excellent strength and durability under heavy loads. With welded joints and reinforced edges, the Forkhead maintains structural integrity even during demanding construction activities, reducing the risk of accidents and improving worker safety.

Ease of use is another key feature. The Forkhead can be quickly attached to adjustable steel props and removed after use. Its standardized design allows it to fit a wide range of prop diameters and beam sizes, making it highly compatible with existing formwork systems. This reduces labor time, simplifies installation, and increases overall productivity on site.

Additionally, the Forkhead is highly reusable and corrosion-resistant. Durable finishes such as painted, powder-coated, or galvanized surfaces protect against rust and wear, extending the accessory’s service life. Contractors can use the Forkhead across multiple projects without compromising safety or performance.

Overall, the Forkhead combines load stability, strength, compatibility, and ease of use, making it an indispensable accessory for contractors, formwork suppliers, and construction professionals seeking reliable and safe temporary support solutions.

The Forkhead is manufactured according to strict quality standards to ensure consistent performance in formwork applications. Typical technical parameters include:

Material: High-strength carbon steel

Type: Adjustable steel prop accessory

Surface Treatment: Painted, powder-coated, or hot-dip galvanized

Design: Forked head with reinforced side plates

Compatible Prop Diameter: Standard steel props (inner diameter 48–60 mm, outer diameter 60–76 mm)

Beam Compatibility: Supports standard timber, steel, or precast beams

Load Capacity: Designed to safely transfer the prop’s rated load to supported beams

Attachment Method: Welded or clamp-on to the steel prop

Durability: Suitable for multiple reuse cycles

The forked structure ensures uniform load distribution and prevents beams from slipping or shifting during concrete placement. Welded joints and reinforced sides provide additional strength under dynamic construction loads.

Forkheads are compatible with most adjustable steel props and can be used with timber beams, steel beams, or precast elements. They are suitable for indoor and outdoor construction sites and are designed for high-cycle usage in repeated construction projects.

Proper installation requires secure placement of the Forkhead on the prop, alignment with the supported beam, and ensuring vertical load transfer. Regular inspection for wear or damage ensures continued safety and reliable performance.

The Forkhead is an essential accessory in temporary shoring and formwork systems, designed to support horizontal elements during concrete casting. Its forked design provides a cradle for beams, enabling secure positioning and load transfer from the supported structure to the vertical steel prop.

The working principle is straightforward: the horizontal beam rests in the forkhead, which distributes the load evenly across the prop head. This prevents localized stress points that could damage the beam or compromise stability. The Forkhead can accommodate slight beam movement during alignment while maintaining safety and precision.

Compared to using flat prop heads or timber wedges, the Forkhead offers superior stability, safety, and reusability. It ensures that horizontal elements remain in position during concrete pouring, reducing the need for additional temporary supports and minimizing construction errors.

Forkheads are widely used in residential, commercial, and infrastructure projects. Applications include slab edge support, precast panel installation, beam bracing, and floor formwork systems. Their use ensures accurate alignment, uniform load distribution, and enhanced site safety.

For safe and effective use, Forkheads must be properly attached to adjustable steel props, aligned with the supported beam, and used within the prop’s rated load limits. With proper usage and maintenance, Forkheads can be reused across multiple projects, offering an economical and reliable solution for temporary beam support.

Visual materials are essential to demonstrate the structure, function, and application of the Forkhead. Images help users understand compatibility, installation methods, and practical benefits.

Common image types include:

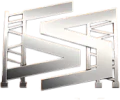

Product Overview: Images showing the Forkhead, highlighting the forked structure, reinforcement plates, and surface finish.

Detail Views: Close-ups of welds, edges, and attachment mechanisms to show build quality and durability.

Compatibility Demonstration: Photos showing Forkheads attached to different adjustable steel props and supporting timber, steel, or precast beams.

On-Site Applications: Images of Forkheads in action during slab formwork, beam installation, and precast panel alignment.

Installation Process: Step-by-step visuals illustrating proper positioning, alignment, and secure attachment to the prop.

These visuals are widely used in catalogs, technical manuals, training guides, and online product pages. They provide practical guidance for safe installation, highlight the Forkhead’s reliability, and demonstrate its value as a reusable construction accessory.

By combining detailed technical descriptions with clear visuals, contractors, engineers, and site managers can confidently select the Forkhead as a safe, efficient, and durable solution for temporary support of beams and slabs.