Pressed Couplers are engineered to deliver strength, efficiency, and safety in reinforced concrete construction. One of their main advantages is the mechanical splicing capability, which allows two rebars to be connected end-to-end without overlapping. This reduces steel usage, minimizes congestion in heavily reinforced areas, and ensures smooth concrete placement.

Durability and reliability are critical selling points. Pressed Couplers are manufactured with high-strength alloy steel and precision pressing, resulting in a uniform and secure connection. They are designed to transfer the full tensile and compressive load of the rebar, maintaining structural integrity according to engineering design requirements.

Ease of installation is another key benefit. Pressed Couplers can be installed quickly on-site or pre-fitted during rebar fabrication. The system requires minimal tools and labor, accelerating construction schedules and improving productivity. Compatibility with multiple rebar sizes and grades makes Pressed Couplers versatile across a range of reinforced concrete projects.

Safety is enhanced due to the precision manufacturing process. Each coupler provides a consistent, reliable joint that reduces the risk of weak points in the concrete structure. Corrosion-resistant finishes or coatings further extend service life, even under harsh environmental conditions.

Overall, Pressed Couplers provide strength, speed, efficiency, and reliability, making them an ideal choice for engineers, contractors, and construction professionals seeking high-quality mechanical splicing solutions in reinforced concrete projects.

Pressed Couplers are manufactured according to strict quality and safety standards. Typical technical parameters include:

Material: High-strength alloy steel, precision pressed

Type: Standard pressed mechanical coupler

Diameter Compatibility: Rebars from 12 mm to 50 mm (custom sizes available)

Load Capacity: Equal to or exceeding the yield strength of the connected rebars

Surface Treatment: Galvanized, epoxy-coated, or anti-corrosion treated

Standards Compliance: ISO 15835, BS 8666, ASTM A1034, or equivalent

Application: Mechanical splicing in reinforced concrete structures, including precast and cast-in-place elements

The pressing process ensures consistent dimensional accuracy, high load-bearing capacity, and uniform stress distribution across the joined bars. The coupler is designed to securely hold rebars under tension and compression loads as required by structural designs.

Installation requires proper alignment of rebar ends, pressing using hydraulic or mechanical tools, and verification of secure connection. Pressed Couplers can be used in high-rise buildings, bridges, precast panels, industrial facilities, and infrastructure projects.

Regular inspection for surface damage, corrosion, or misalignment before casting ensures safety and performance. When installed correctly, Pressed Couplers provide a strong, durable, and reliable connection for mechanically spliced rebar systems.

Pressed Couplers are widely used in reinforced concrete construction to provide mechanical continuity between steel rebars. They eliminate the need for extended lap splicing, reducing material use and congestion in heavily reinforced sections.

The couplers operate on the principle of mechanical interlock achieved through pressing. Rebar ends are inserted into the coupler, which is then pressed with hydraulic or mechanical tools to deform the internal surfaces, creating a secure, high-strength joint. This ensures full load transfer and reliable structural performance.

Compared to traditional lap splices, Pressed Couplers offer significant advantages: faster installation, reduced steel consumption, cleaner concrete placement, and improved structural reliability. They are particularly useful in high-rise buildings, bridges, precast elements, and projects with dense reinforcement.

Proper selection and installation are essential. Couplers must match the rebar diameter and grade, and pressing should be performed according to manufacturer specifications. Quality control checks, including visual inspection and load testing, help ensure the joint meets design requirements.

Pressed Couplers provide efficient, durable, and safe mechanical splicing solutions, improving construction quality, reducing labor and material costs, and supporting modern reinforced concrete engineering practices. Their corrosion-resistant finish and high-strength steel construction ensure long-term performance under demanding conditions.

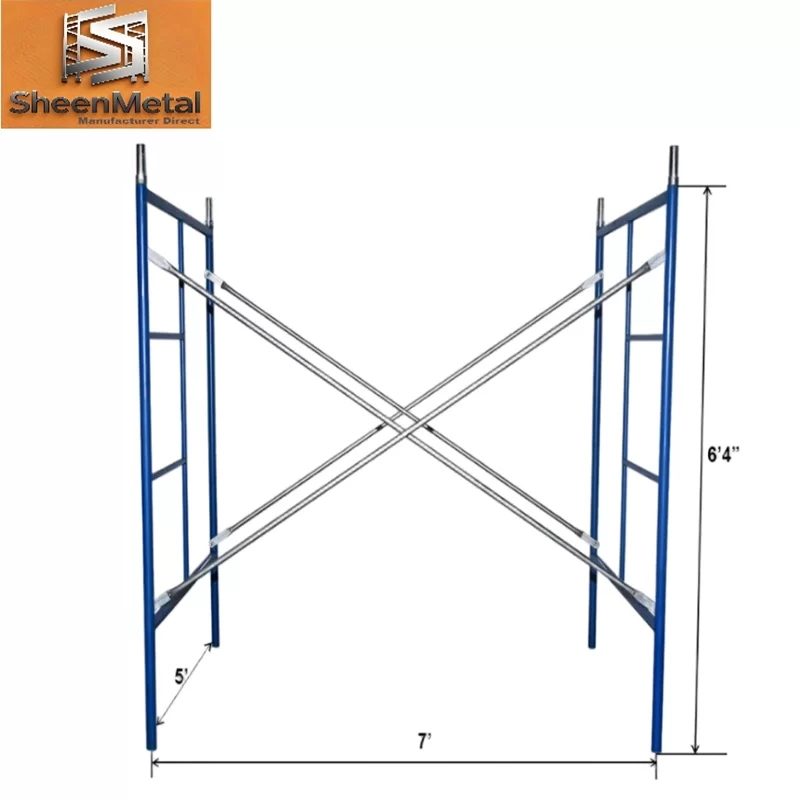

Visual presentation is essential to demonstrate the structure, installation, and practical application of Pressed Couplers. High-quality images help engineers, contractors, and site supervisors understand the installation method, structural benefits, and compatibility with rebar systems.

Common image types include:

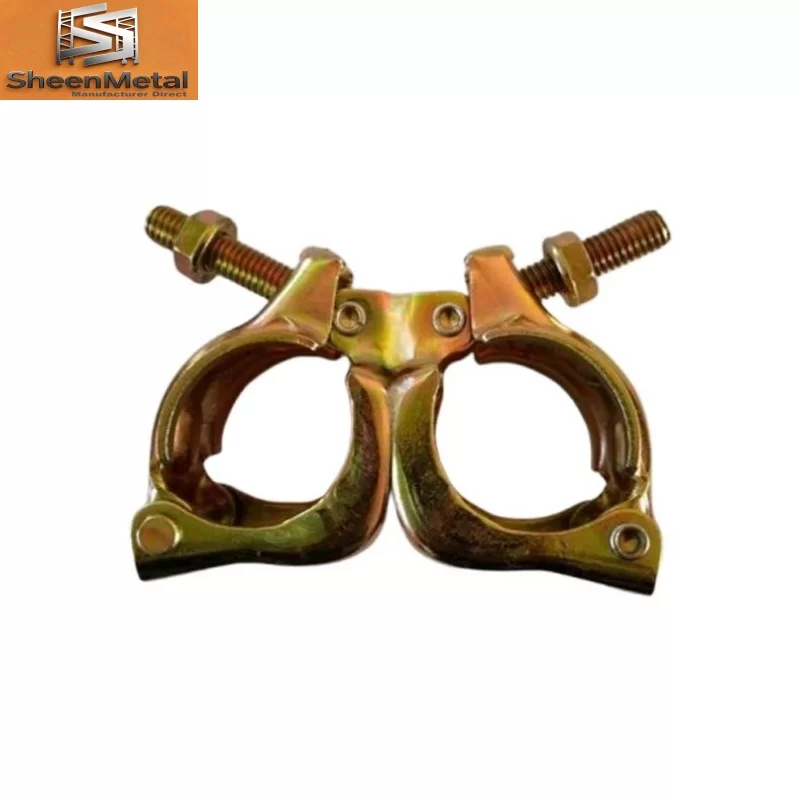

Product Overview: Individual Pressed Couplers showing precision pressing and steel quality

Detail Images: Close-ups of coupler internal surfaces, deformation patterns, and surface coatings

Installation Examples: Photos of couplers connecting rebar in vertical and horizontal configurations

On-Site Applications: Couplers used in high-rise building columns, bridge construction, precast panels, and industrial structures

Embedded Applications: Images showing couplers installed during casting for seamless bar connections

Installation Process: Step-by-step visuals showing rebar insertion, pressing using mechanical tools, and verification of secure connection

These images are used in catalogs, technical manuals, online product pages, and training guides. They provide practical guidance for safe installation, highlight the coupler’s strength and durability, and demonstrate its versatility in reinforced concrete projects.

Combining technical specifications with high-quality visuals ensures that engineers and contractors can confidently select Pressed Couplers as a reliable, efficient, and durable mechanical splicing solution for modern construction projects.