Hollow PP Formwork provides a combination of lightweight design, durability, and rapid installation, making it an ideal choice for modern construction projects. One of its key advantages is modularity—the formwork panels can be easily connected to form walls, columns, and other concrete structures of varying shapes and sizes. This flexibility allows contractors to complete complex designs efficiently while maintaining high precision.

Ease of assembly and disassembly is another significant benefit. Hollow PP Formwork panels are lightweight and ergonomic, reducing labor requirements and installation time compared to traditional timber or steel formwork. The system can be handled by small teams without heavy machinery, improving productivity on site.

Durability and corrosion resistance are essential advantages. Made from high-quality polypropylene, the panels withstand repeated use, exposure to water, and contact with concrete without deformation. The material is also chemically resistant, making it suitable for use in harsh environments, including industrial facilities, tunnels, and water-retaining structures.

Additionally, Hollow PP Formwork produces a smooth concrete surface finish, reducing the need for additional plastering or finishing work. Its eco-friendly and reusable nature promotes sustainability by reducing timber usage and minimizing construction waste. The system is compatible with accessories such as corner panels, wedges, and tie rods, further enhancing versatility.

Overall, Hollow PP Formwork combines lightweight handling, durability, efficiency, and sustainability, making it a reliable solution for contractors, engineers, and construction managers seeking fast, high-quality formwork for walls, columns, and slabs.

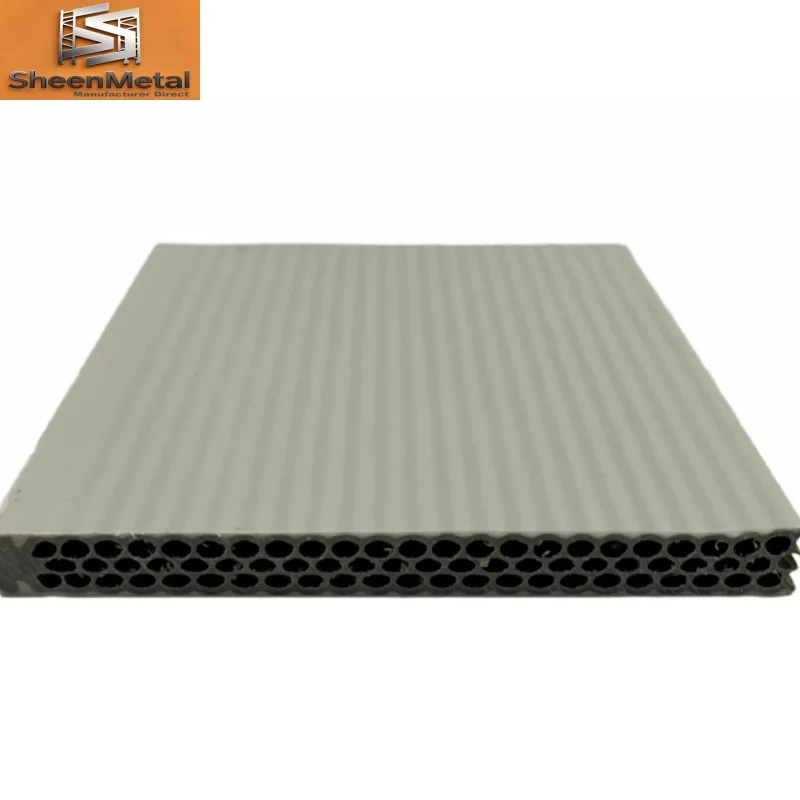

Hollow PP Formwork is manufactured to meet international standards for strength, durability, and safety. Typical technical parameters include:

Material: High-strength polypropylene (PP)

Panel Size: Standard panels 600 mm × 600 mm, 600 mm × 1200 mm, or custom sizes

Panel Thickness: 6–10 mm, depending on design load

Load Capacity: Supports up to 5–8 kN/m² when properly braced

Weight: Lightweight, approximately 4–8 kg per panel (size-dependent)

Surface Finish: Smooth, high-quality concrete finish

Durability: Resistant to corrosion, moisture, and chemical exposure

Accessories: Corner panels, tie rods, wedges, clamps, and connectors

Application: Wall formwork, column formwork, slab formwork, and decorative concrete panels

Hollow PP panels are designed for modular assembly, with interlocking edges and accessories to ensure precise alignment. The lightweight material allows fast handling, reducing installation time and labor costs. Panels can be used repeatedly, maintaining consistent shape, dimension, and surface quality over multiple projects.

Proper bracing, alignment, and support are essential to ensure safety and load-bearing performance during concrete pouring. Regular inspection for cracks, deformation, or surface wear helps maintain durability and long-term performance.

Hollow PP Formwork is an innovative solution for lightweight, modular, and reusable concrete formwork. Made from high-quality polypropylene, the panels are corrosion-resistant, water-resistant, and chemically stable, making them ideal for various construction environments, including wet conditions, industrial sites, and outdoor projects.

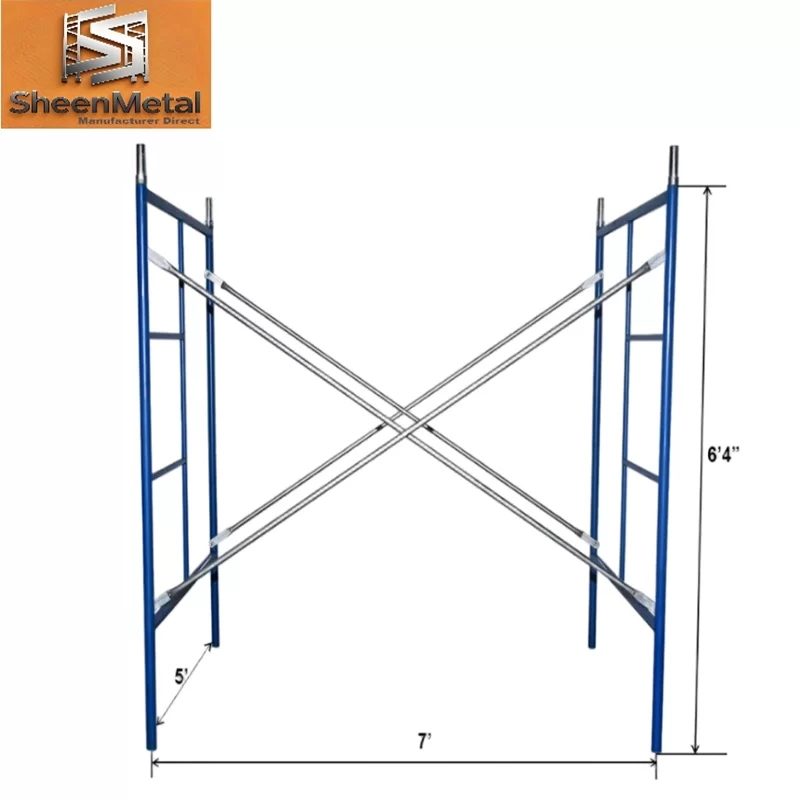

The system works by connecting modular panels to create walls, columns, or slabs, supported with tie rods, wedges, and braces. Hollow PP Formwork provides dimensional stability, ensuring straight edges, uniform thickness, and smooth concrete surfaces, reducing post-pour finishing work.

Compared with traditional timber or steel formwork, Hollow PP Formwork is significantly lighter and easier to handle, reducing labor costs and installation time. Its modular design allows reuse across multiple projects, promoting cost-effectiveness and sustainability. The panels are also eco-friendly, minimizing timber usage and construction waste.

Safety is enhanced due to the lightweight yet durable nature of the panels. Proper assembly ensures that panels remain aligned and braced during concrete pouring, preventing accidents or deformation. Hollow PP Formwork is also suitable for intricate designs, curves, and architectural features, providing flexibility without compromising structural integrity.

Routine maintenance involves cleaning the panels after use, checking for cracks or deformations, and proper storage to extend service life. When used correctly, Hollow PP Formwork offers efficient, durable, and high-quality concrete forming, improving workflow, reducing labor, and supporting sustainable construction practices.

Visual content is essential for demonstrating the structure, installation, and practical applications of Hollow PP Formwork. High-quality images help engineers, contractors, and site supervisors understand assembly, safety features, and versatility.

Common image types include:

Product Overview: Individual hollow PP formwork panels showing thickness, surface finish, and interlocking edges

Detail Images: Close-ups of connectors, corner panels, tie rod holes, and wedges

Installation Examples: Panels assembled for walls, columns, slabs, or decorative concrete features

On-Site Applications: Panels used in residential, commercial, and industrial construction, including high-rise buildings, tunnels, and water-retaining structures

Assembly Demonstration: Step-by-step visuals showing modular panel connection, bracing, tie rods, and alignment

Concrete Pouring: Images demonstrating stability and smooth surface finish after concrete casting

These images are widely used in catalogs, technical manuals, online product listings, and training guides. They provide practical guidance for proper installation, highlight durability and precision, and demonstrate the system’s versatility for multiple concrete forming applications.

By combining technical specifications with high-quality visuals, engineers, contractors, and project managers can confidently select Hollow PP Formwork for safe, durable, efficient, and sustainable concrete construction projects.