Formwork Spring Clamps provide secure, fast, and reliable fastening for formwork panels during concrete casting, ensuring precision, stability, and safety. One of the primary advantages is the spring-loaded mechanism, which allows quick attachment and detachment without the need for additional tools, reducing labor costs and saving time on-site.

Ease of use enhances site productivity. The spring mechanism provides quick adjustment and consistent clamping pressure without manual tightening, allowing small teams to assemble or adjust formwork efficiently. Safety is also improved because panels are held firmly in place, reducing the risk of accidents caused by shifting or loose formwork.

Overall, Formwork Spring Clamps combine strength, reliability, speed, and versatility, making them indispensable tools for engineers, contractors, and site supervisors seeking efficient, safe, and reusable formwork solutions.

Material: High-strength spring steel or reinforced steel

Clamping Range: 10–50 mm (depending on model)

Load Capacity: Designed to withstand high lateral and vertical concrete pressures

Dimensions: Standard lengths 100–200 mm, adjustable jaw openings

Surface Treatment: Galvanized, powder-coated, or painted for corrosion resistance

Weight: Lightweight for easy handling and repositioning

Compatibility: Timber, plywood, or hollow PP formwork panels of varying thickness

Application: Secures formwork panels for walls, columns, slabs, beams, and decorative concrete structures

The spring clamp works by applying consistent clamping force across the panel edges, preventing movement and ensuring correct alignment during concrete pouring. The spring mechanism allows for quick attachment, adjustment, and removal without compromising strength or safety.

Regular inspection is essential to check for wear, rust, or deformation of the jaws and spring mechanism. Correct installation and usage according to panel thickness and recommended spacing maintain stability and prevent accidents or formwork misalignment during construction.

Formwork Spring Clamps are essential accessories in modern formwork systems, providing secure and reusable fastening of panels during concrete casting. Their spring-loaded mechanism allows the clamps to grip the edges of timber, plywood, or hollow PP formwork panels firmly, maintaining alignment and stability under high concrete pressure.

Compared to traditional bolted or fixed clamps, spring clamps offer faster installation and removal, saving time and reducing labor requirements. The consistent clamping force ensures that formwork panels do not shift, bow, or separate during concrete pouring, leading to smooth surface finishes and precise dimensions.

Formwork Spring Clamps improve safety, efficiency, and quality on construction sites. By securing panels firmly in place, they prevent accidents caused by slipping or misaligned panels and contribute to a consistent concrete finish. Lightweight and reusable, these clamps are an eco-friendly and cost-effective solution for modern construction projects.

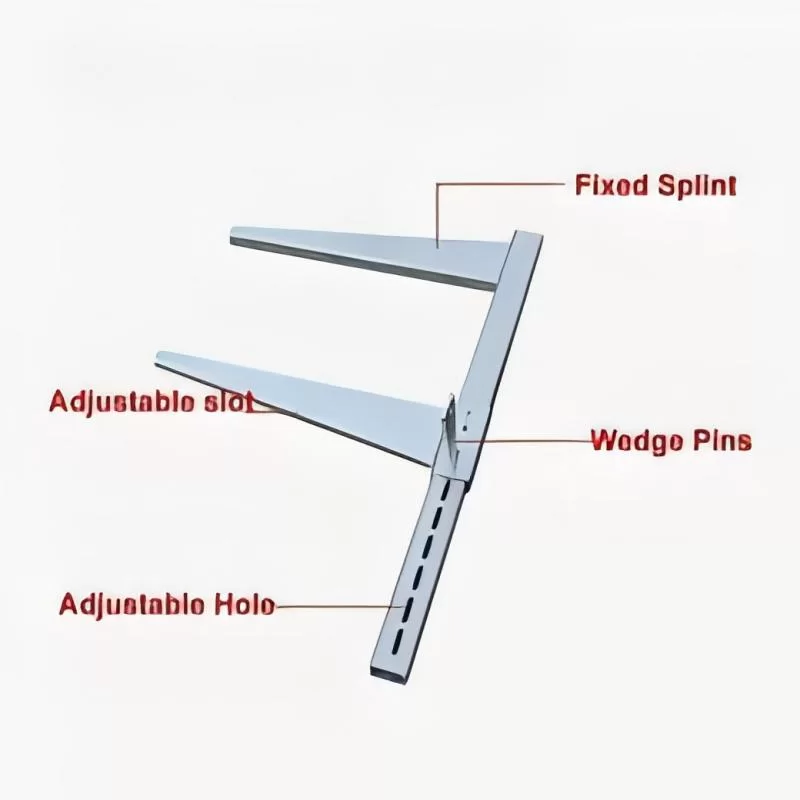

Visual content is essential for demonstrating the structure, installation, and practical applications of Formwork Spring Clamps. High-quality images help engineers, contractors, and site supervisors understand assembly, safety, and efficiency.

Common image types include:

Product Overview: Individual spring clamps showing spring mechanism, jaws, and steel construction

Detail Images: Close-ups of spring tension, jaw shape, protective coating, and edges

Installation Examples: Clamps securing timber, plywood, or hollow PP formwork panels on walls, slabs, or columns

On-Site Applications: Images of multiple clamps holding panels during concrete pouring on residential, commercial, or industrial construction sites

Assembly Demonstration: Step-by-step visuals showing panel placement, clamp attachment, and adjustment

Finished Surface: Photos showing smooth concrete finishes after formwork removal, highlighting alignment and stability

These images are widely used in catalogs, technical manuals, online product listings, and training guides. They provide practical guidance for proper installation, highlight strength and durability, and demonstrate versatility for various formwork applications.

Combining technical specifications with high-quality visuals ensures that engineers, contractors, and project managers can confidently select Formwork Spring Clamps for safe, efficient, and reliable panel securing in all concrete construction projects.