The Middle East Steel Prop is designed to deliver exceptional strength and reliability in challenging construction environments. One of its key selling points is its high load-bearing capacity, making it suitable for large concrete slabs, beams, and heavy formwork systems commonly used in commercial, residential, and infrastructure projects across the Middle East.

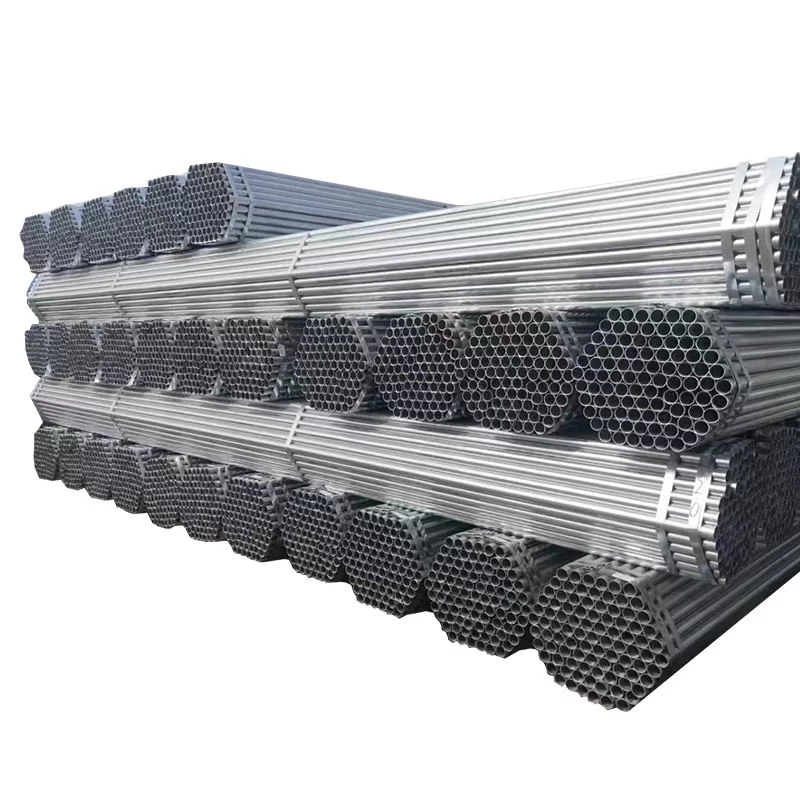

Durability is a major advantage of this steel prop. It is manufactured from high-grade carbon steel and commonly treated with painted, powder-coated, or hot-dip galvanized finishes to provide excellent resistance to corrosion, dust, and harsh weather conditions. This makes it particularly well-suited for outdoor construction sites and long-term projects in hot and dry climates.

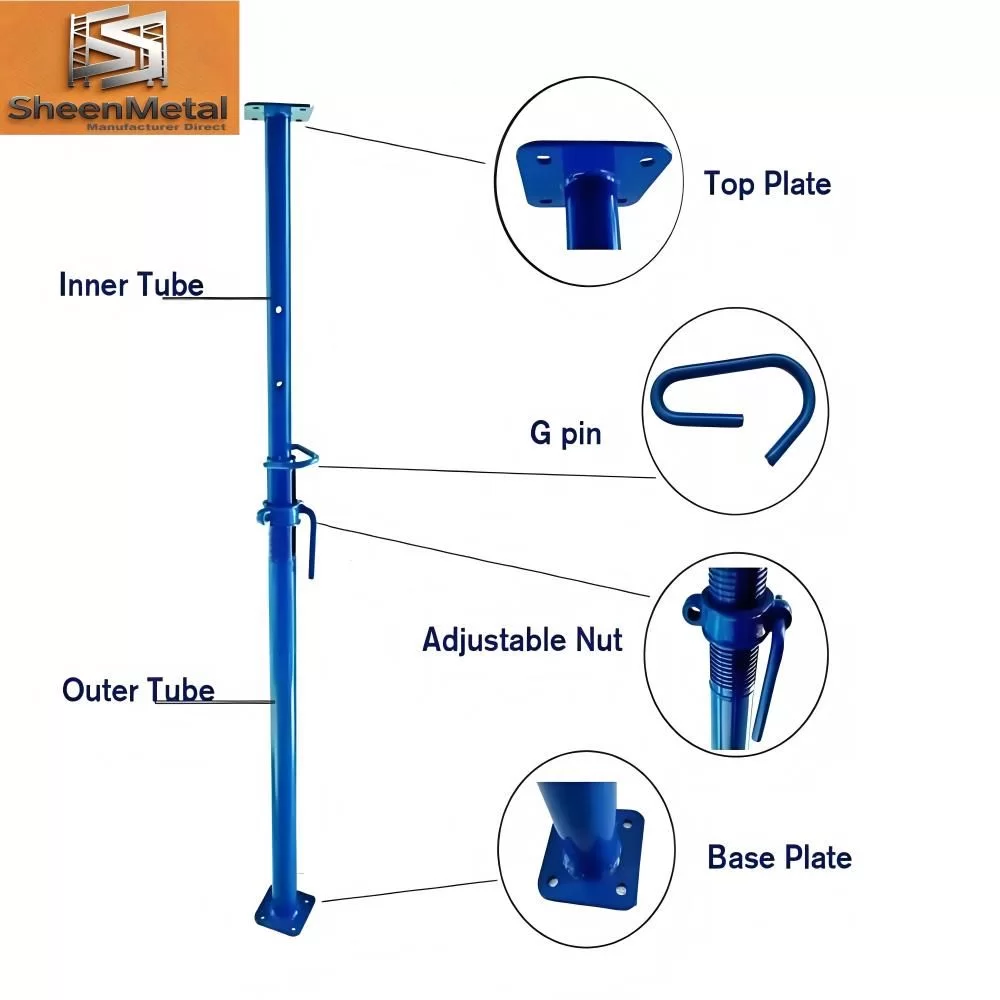

Another important selling point is its wide adjustment range and simple operation. The telescopic design, combined with a threaded sleeve and safety pin mechanism, allows precise height adjustment and secure positioning. This flexibility improves site efficiency and reduces the need for multiple prop sizes on the same project.

Ease of installation and reuse further enhances its value. Middle East Steel Props can be quickly installed and dismantled without specialized tools, reducing labor costs and construction time. The wide base and top plates ensure stable load transfer, enhancing safety during concrete pouring and curing stages.

Overall, Middle East Steel Props offer a strong combination of load capacity, durability, adjustability, and cost efficiency, making them a preferred choice for contractors, formwork suppliers, and project developers across the Middle East region.

The Middle East Steel Prop is manufactured according to standardized technical specifications to ensure consistent performance and safety. While dimensions and load ratings may vary depending on the model, typical technical parameters include:

Material: High-strength carbon steel

Type: Adjustable telescopic steel prop

Surface Treatment: Painted, powder-coated, or hot-dip galvanized

Adjustment Mechanism: Threaded sleeve with safety pin locking system

Height Range: Commonly from 2.0 m to 4.0 m (custom sizes available)

Load Capacity: Varies by extension height, typically up to 20–30 kN

Inner Tube Diameter: Approx. 48–60 mm

Outer Tube Diameter: Approx. 60–76 mm

Base Plate: Welded steel plate for stable ground contact

Top Plate: Flat plate or U-head for formwork beam support

The threaded adjustment system allows fine height tuning, while the safety pin ensures secure positioning under load. This dual mechanism improves both precision and operational safety.

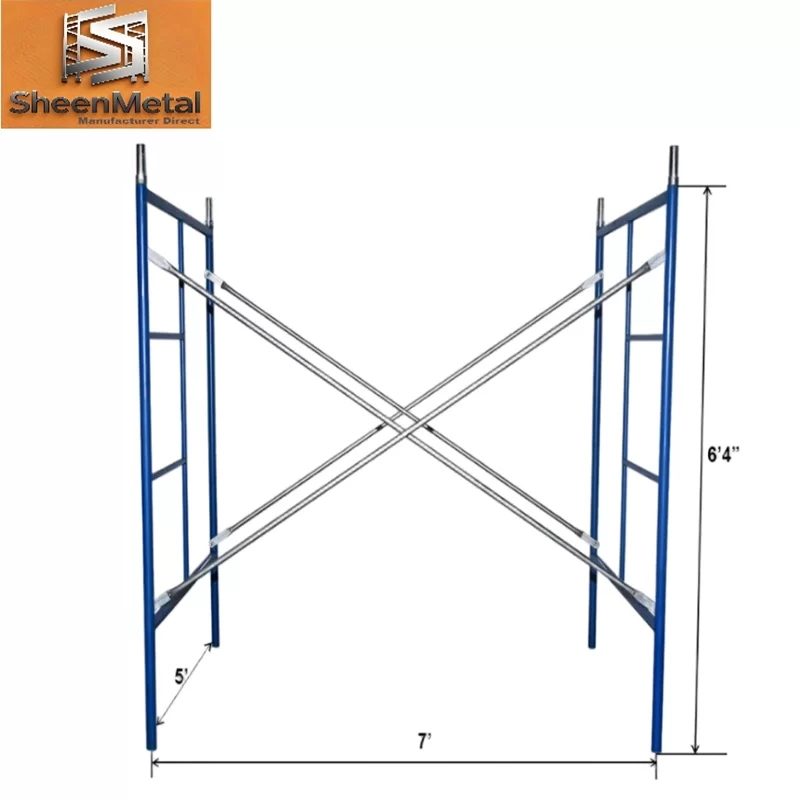

Middle East Steel Props are compatible with various formwork systems, including timber beams, steel beams, and plywood panels. Their robust construction supports repetitive use in high-cycle construction environments.

For best performance, props should be installed vertically on solid foundations and used within specified load limits. Regular inspection and proper maintenance help ensure long service life and safe operation on construction sites.

Steel props are essential components in temporary shoring and formwork systems, providing vertical support during concrete placement and curing. The Middle East Steel Prop is designed with regional construction practices and environmental conditions in mind, offering enhanced durability and load performance.

The working principle of a steel prop is based on axial load transfer through a telescopic steel structure. Once adjusted to the required height, the prop transfers loads from slabs or beams directly to the ground. The threaded sleeve allows precise adjustment, while the safety pin prevents accidental movement under load.

Compared with timber supports, steel props provide superior strength, dimensional stability, and reusability. They are not affected by moisture, warping, or cracking, making them more reliable for repeated use. Compared with lighter aluminum props, steel props offer higher load capacity and better suitability for heavy-duty construction.

Middle East Steel Props are widely used in residential buildings, commercial complexes, warehouses, bridges, and infrastructure projects. They are also commonly used in large-scale developments where safety, efficiency, and consistency are critical.

Proper installation and usage are essential for safe operation. Props should be placed vertically, evenly spaced according to engineering requirements, and securely locked before loading. Regular inspection ensures continued safety and performance. With correct use, Middle East Steel Props significantly enhance construction efficiency, accuracy, and on-site safety.

Product and application images are essential for clearly demonstrating the structure, functionality, and real-world use of Middle East Steel Props. These visuals help customers and contractors quickly understand installation methods and performance benefits.

Typical images include:

Product Overview: Clear images showing the complete steel prop, including inner and outer tubes, threaded sleeve, base plate, and top plate.

Detail Views: Close-up photos highlighting the adjustment mechanism, safety pin, weld quality, and surface treatment.

Surface Finishes: Comparative images of painted, powder-coated, and galvanized versions to illustrate corrosion resistance options.

On-Site Applications: Photos of Middle East Steel Props supporting slabs and formwork in residential, commercial, and infrastructure construction projects.

Installation Demonstrations: Step-by-step visuals showing correct positioning, height adjustment, and load application.

These images provide practical guidance for safe installation while reinforcing product quality and reliability. They are widely used in catalogs, technical manuals, training materials, and online product pages.

By combining detailed visuals with technical explanations, customers can confidently evaluate how Middle East Steel Props meet project requirements, ensuring safe use, efficient installation, and long-term value on construction sites.