Scaffolding Caster Wheels are essential accessories for mobile scaffolding systems, offering mobility, safety, and convenience. One of the primary advantages is their ability to allow scaffold towers or platforms to be moved easily without disassembly. This increases productivity on construction sites by enabling rapid repositioning of work platforms across multiple locations.

Safety and stability are central to the design. High-quality caster wheels feature locking mechanisms to prevent unintended movement while personnel are on the scaffold. Swivel designs provide 360° rotation, allowing smooth navigation around corners and obstacles. Heavy-duty materials such as reinforced steel for the frame and polyurethane or rubber for the wheel ensure high load-bearing capacity and durability under rigorous site conditions.

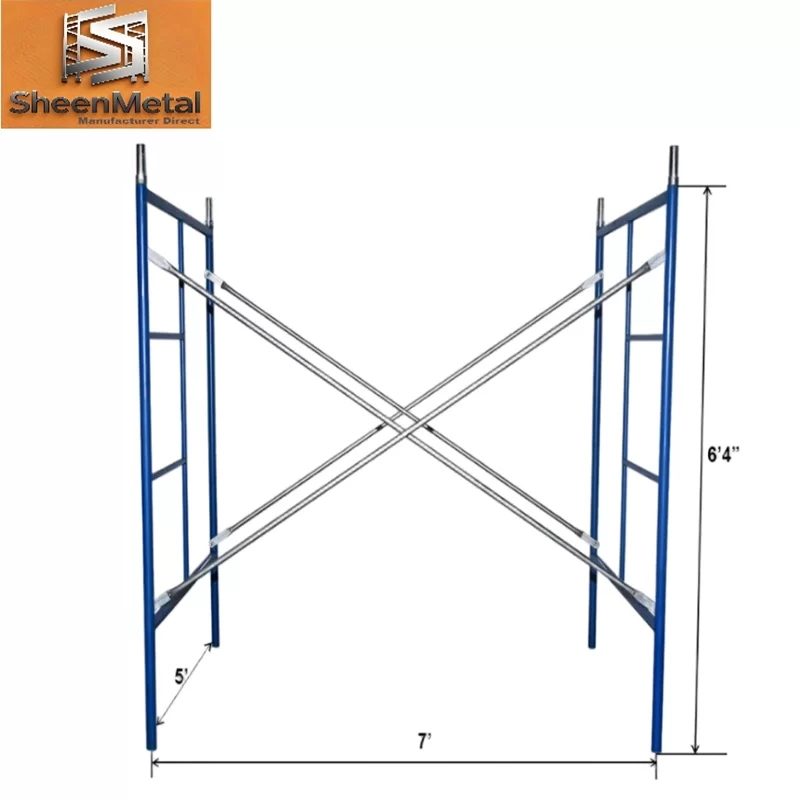

Another key benefit is versatility. Caster wheels are compatible with various scaffolding systems, including frame scaffolding, Ringlock scaffolding, and Kwikstage scaffolding. Adjustable stems or mounting plates allow secure attachment to scaffolding standards of different diameters and profiles, providing flexibility for diverse construction setups.

Durability and reliability are further enhanced by corrosion-resistant finishes, such as zinc plating or hot-dip galvanization, ensuring long-term performance even in harsh environmental conditions. Their robust design enables repeated use across multiple projects, offering a cost-effective and efficient solution for mobile scaffolding.

Overall, Scaffolding Caster Wheels combine strength, mobility, safety, and durability, making them a preferred choice for contractors, engineers, and maintenance teams who require reliable and easily movable scaffold platforms.

Scaffolding Caster Wheels are engineered to meet international safety and performance standards. Typical technical parameters include:

Material: High-strength steel frame with polyurethane or rubber wheel

Wheel Diameter: 125 mm, 150 mm, 200 mm, or custom sizes

Load Capacity: 200–500 kg per wheel, depending on model

Swivel Type: 360° rotation for flexible maneuvering

Locking Mechanism: Dual brake for wheel and swivel lock

Stem/Mounting: Adjustable threaded stem or plate mount for secure attachment

Surface Treatment: Galvanized or zinc-plated for corrosion resistance

Compatibility: Suitable for most frame, Ringlock, and Kwikstage scaffolding

These caster wheels are designed to provide both mobility and stability. The swivel mechanism allows easy direction changes, while the locking brakes secure the scaffold in place during work. Polyurethane wheels provide smooth movement on hard surfaces without damaging floors, while rubber wheels offer traction on uneven surfaces.

Regular inspection is recommended to ensure wheel integrity, proper rotation, and brake functionality. Correct installation and use according to load limits and manufacturer specifications guarantee safety and long-term performance.

Scaffolding Caster Wheels are an important accessory for mobile scaffolding systems, providing a combination of mobility, stability, and safety. By mounting these wheels to scaffold standards, entire towers or platforms can be repositioned without disassembly, saving labor and increasing site efficiency.

The caster wheel system consists of a wheel, swivel frame, stem or mounting plate, and locking mechanism. The swivel allows 360° rotation, enabling smooth movement in tight spaces and around obstacles. Locking brakes secure the wheel and swivel to prevent movement while personnel are working on the platform.

Compared to fixed scaffolding, mobile scaffolds with caster wheels are highly versatile, suitable for maintenance, painting, electrical work, indoor installations, and temporary access in warehouses or construction sites. The mobility allows workers to cover larger areas efficiently without the need to dismantle and reassemble scaffolding.

Wheel material is crucial for performance. Polyurethane wheels are durable, smooth, and suitable for hard indoor surfaces, while rubber wheels provide shock absorption and traction on uneven or outdoor surfaces. The steel frame and corrosion-resistant coating ensure that the caster wheel can support heavy loads and withstand harsh environmental conditions.

Proper use includes securing the scaffold with the wheel locks before work, ensuring weight limits are not exceeded, and routinely inspecting wheels for wear, deformation, or damage. With these precautions, Scaffolding Caster Wheels provide safe, reliable, and efficient mobility, making them essential for modern construction and maintenance projects.

Visual content is essential for demonstrating the structure, installation, and applications of Scaffolding Caster Wheels. High-quality images help engineers, contractors, and site supervisors understand their operation, compatibility, and safety features.

Common image types include:

Product Overview: Individual caster wheels showing wheel material, frame, and swivel mechanism

Detail Images: Close-ups of wheel treads, swivel rotation, mounting stem, and locking mechanism

Installation Examples: Wheels mounted on frame scaffolding, Ringlock scaffolding, or Kwikstage scaffolds

On-Site Applications: Mobile scaffold towers in warehouses, construction sites, maintenance areas, and painting projects

Locking Mechanism Demonstration: Images showing the wheel brake and swivel lock engaged

Operational Guidance: Step-by-step visuals showing scaffold movement, positioning, and final securing with locks

These images are commonly used in catalogs, technical manuals, online product listings, and training guides. They provide practical guidance for safe installation and use, highlight mobility and load-bearing capabilities, and demonstrate versatility in different construction and maintenance projects.

By combining technical specifications with high-quality visuals, contractors, engineers, and facility managers can confidently select Scaffolding Caster Wheels for safe, efficient, and reliable scaffold mobility across a variety of applications.