Casting Couplers are widely used in reinforced concrete construction due to their strength, efficiency, and ease of use. One of the primary advantages is their ability to provide mechanical continuity between steel rebars. Unlike traditional lap splicing, which requires overlapping bars and increased material usage, Casting Couplers join bars end-to-end while maintaining full load-bearing capacity. This results in more efficient use of steel and reduced congestion in concrete sections.

Another key feature is high structural integrity and reliability. Casting Couplers are precision-engineered to match the diameter and grade of the rebar, ensuring uniform stress distribution and preventing weak points in the structure. They are designed to withstand tensile and compressive forces according to international building codes.

Ease of installation is another major benefit. Couplers can be attached quickly on-site or embedded during casting, allowing for faster construction schedules. They are compatible with various diameters and grades of steel reinforcement, making them versatile for multiple construction scenarios.

Durability is also critical. With corrosion-resistant coatings or stainless steel construction, Casting Couplers ensure long-term performance even in harsh environmental conditions. Reusable molds or embedded types reduce labor and improve site productivity.

Overall, Casting Couplers offer strength, safety, material efficiency, and speed, making them a preferred choice for engineers, contractors, and construction professionals seeking high-quality mechanical splicing solutions in reinforced concrete projects.

Casting Couplers are manufactured to meet stringent standards for reinforced concrete construction. Typical technical parameters include:

Material: High-strength carbon steel or alloy steel

Type: Threaded, compression, or wedge-type couplers

Diameter Compatibility: Rebar diameters from 12 mm to 50 mm (custom sizes available)

Load Capacity: Equal to or exceeding the yield strength of the connected rebar

Surface Treatment: Galvanized, epoxy-coated, or stainless steel for corrosion resistance

Standards Compliance: ISO 15835, BS 8666, ASTM A1034, or equivalent

Application: Mechanical splicing in reinforced concrete structures, embedded during casting or post-tensioned

Casting Couplers are engineered to ensure uniform stress distribution across the connected bars. Threaded couplers provide high-torque connections, while wedge or compression couplers allow fast assembly without specialized tools. They can be used in precast concrete elements, high-rise buildings, bridges, industrial facilities, and infrastructure projects.

Installation requires proper alignment, torque control (for threaded types), and adherence to manufacturer guidelines. Correct installation ensures full structural performance and compliance with design codes. Regular inspection of couplers before concrete pouring ensures safety and reliability.

Casting Couplers are essential mechanical connectors in reinforced concrete construction. Their main function is to transfer loads between rebars, ensuring continuity in tension and compression zones without relying on overlapping bar lengths.

The working principle is based on mechanical interlock or threaded connection. For threaded couplers, steel bars are threaded at the ends and screwed into the coupler, creating a secure joint. Compression or wedge-type couplers grip the rebar when tightened, maintaining load transfer capacity. Unlike lap splices, mechanical couplers reduce congestion in heavily reinforced areas, allowing for cleaner concrete placement and improved structural efficiency.

Advantages include reduced steel usage, faster installation, improved concrete quality, and enhanced structural safety. Couplers are especially useful in high-rise buildings, bridge columns, industrial plants, and precast concrete projects, where bar congestion and long lap requirements may cause construction challenges.

For proper use, couplers must be selected according to rebar diameter, grade, and design load. Threaded couplers require precise threading, torque control, and alignment. Compression or wedge-type couplers must be installed according to manufacturer specifications. Embedded couplers in precast elements ensure seamless connections during assembly on-site.

When properly used, Casting Couplers offer strong, durable, and efficient mechanical splicing solutions, reducing material costs and construction time while maintaining the structural integrity of reinforced concrete elements.

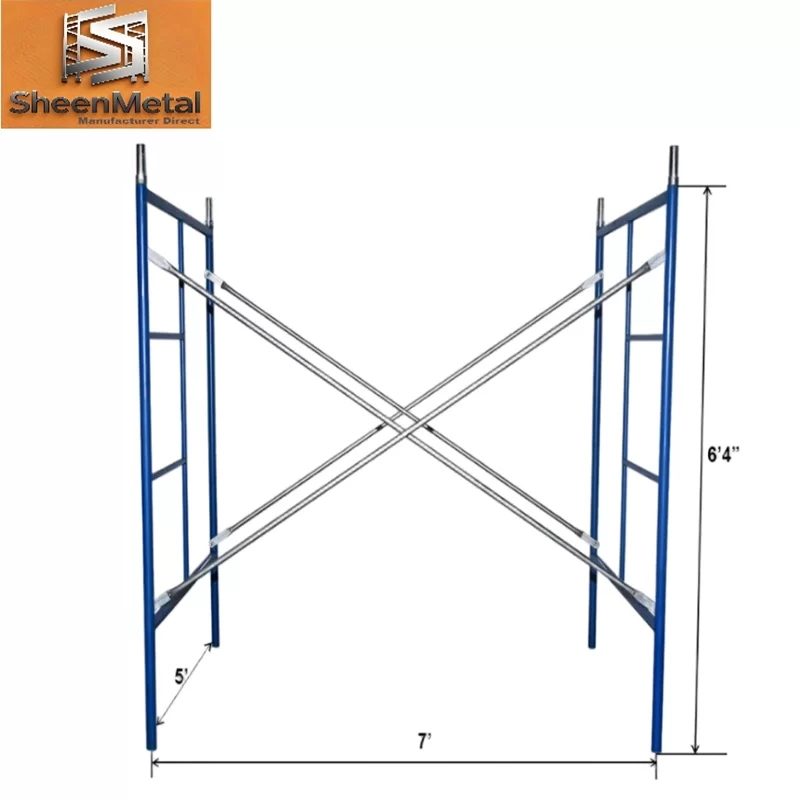

Visual presentation is essential to demonstrate the structure, installation, and applications of Casting Couplers. Clear images help engineers, contractors, and site supervisors understand installation methods, compatibility, and safety features.

Common image types include:

Product Overview: Individual couplers, highlighting threaded, compression, and wedge designs.

Detail Images: Close-ups of threads, grooves, and surface finishes showing corrosion resistance and precision engineering.

Installation Examples: Photos showing couplers connecting rebars in vertical and horizontal configurations.

On-Site Applications: Couplers used in bridge columns, high-rise building columns, industrial structures, and precast concrete panels.

Embedded Applications: Images showing couplers installed during casting for seamless bar connections.

Installation Process: Step-by-step visuals demonstrating alignment, connection, torque application (for threaded types), and verification of load-bearing capacity.

These images are widely used in catalogs, technical manuals, training guides, and online product listings. They provide practical guidance for safe installation, demonstrate the mechanical performance of couplers, and highlight their versatility and durability in reinforced concrete applications.

Combining detailed technical descriptions with high-quality visuals ensures engineers, contractors, and site managers can confidently select Casting Couplers as a safe, efficient, and reliable solution for reinforced concrete projects.