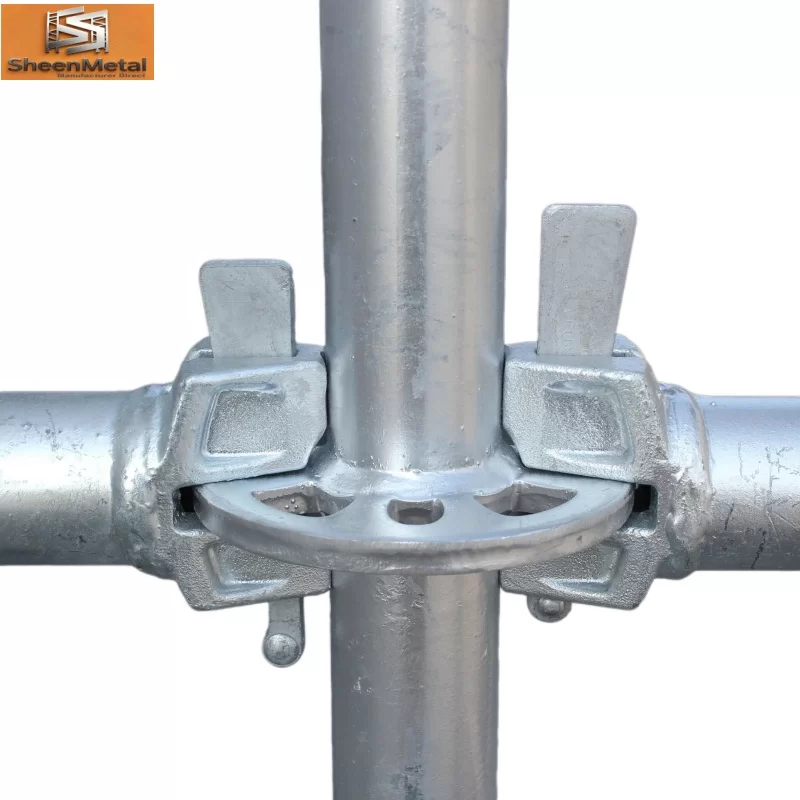

Ringlock Scaffolding is designed to provide maximum efficiency, safety, and versatility on modern construction sites. One of its primary advantages is the unique rosette connection system, which allows horizontal ledgers and diagonal braces to be connected at various angles, enabling flexible scaffolding configurations. This design eliminates the need for traditional couplers, significantly reducing assembly time and labor costs.

Safety and stability are core strengths. The system uses high-strength steel components, including vertical standards, horizontal ledgers, and diagonal braces, providing robust support for workers, tools, and materials. Guardrails, toe boards, and stabilizers enhance safety and ensure compliance with international standards. The rosette design guarantees that each connection is secure and distributes loads evenly across the framework, reducing the risk of structural failure.

Another key benefit is adaptability. Ringlock Scaffolding can be configured to accommodate various heights, widths, and complex geometries, making it ideal for façade works, bridges, industrial maintenance, and architectural projects with curved or irregular structures. Accessories such as ladders, platforms, and base jacks enable customizable configurations, improving efficiency on-site.

Durability and reusability further enhance the system’s appeal. Components are hot-dip galvanized or painted for corrosion resistance, ensuring long service life even in harsh environments. Lightweight yet robust, the system is easy to transport, reposition, and reuse across multiple projects, providing cost-effective scaffolding solutions.

Overall, Ringlock Scaffolding combines speed, flexibility, safety, and durability, making it a preferred choice for contractors, engineers, and facility managers seeking high-quality scaffolding solutions for complex and large-scale construction projects.

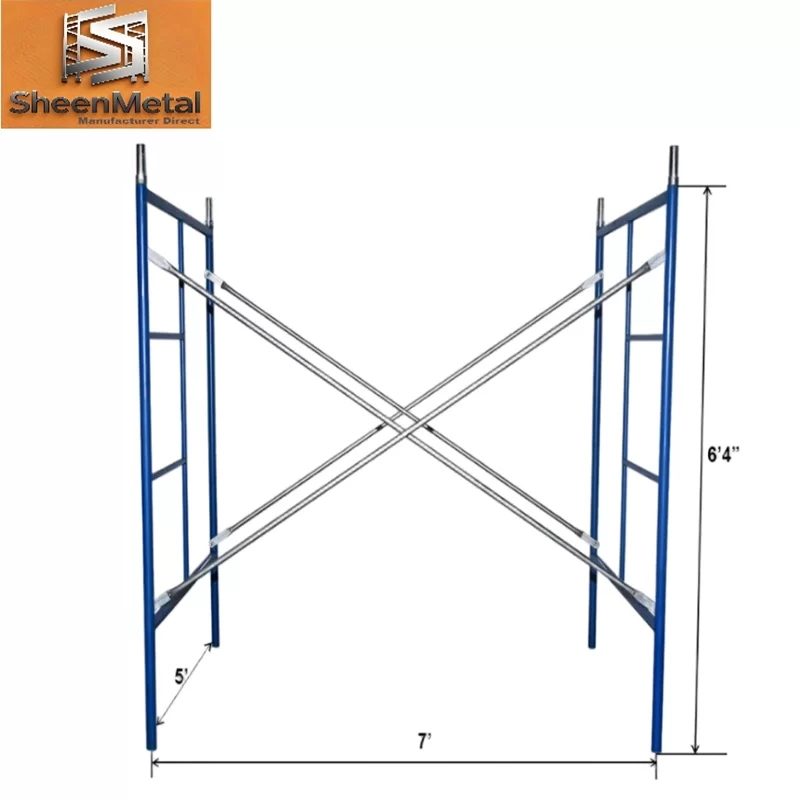

Ringlock Scaffolding is manufactured according to international standards to guarantee strength, safety, and reliability. Typical technical parameters include:

Material: High-strength carbon steel or galvanized steel

Vertical Standard Diameter: 48.3 mm, 60 mm, or customized sizes

Ledger and Brace Tube Diameter: 48.3 mm (standard)

Rosette Connection: 360° rosette design with 8 connection holes

Load Capacity: 200–300 kg per platform level (depending on configuration)

Platform Material: Anti-slip steel or aluminum decking

Height Range: Modular stacking allows scaffolding up to 20 m or more

Surface Treatment: Hot-dip galvanized or painted for corrosion protection

Accessories: Base jacks, ladders, guardrails, stabilizers, and toe boards

The modular rosette design allows rapid vertical stacking and horizontal spans, while base plates or screw jacks ensure stable setup on uneven surfaces. The system can be easily adapted to complex geometries and is compatible with additional scaffolding accessories, providing flexible solutions for industrial, commercial, and residential projects.

Regular inspection and adherence to load ratings are essential to maintain safety and service life. Proper assembly ensures structural integrity, even under high load conditions, making Ringlock Scaffolding suitable for high-rise buildings, bridges, and large-scale infrastructure projects.

Ringlock Scaffolding is a modern modular scaffolding system widely used in construction, maintenance, and industrial projects. Its unique rosette-based connection system allows multiple ledgers and braces to connect at various angles, providing structural flexibility and enabling configurations that are difficult with traditional scaffolding systems.

The system works by combining vertical standards with horizontal ledgers and diagonal braces through the rosette connection. Platforms are installed on ledgers to provide safe working surfaces for personnel and materials. Guardrails and toe boards improve safety, while base jacks ensure stable installation on uneven surfaces.

Compared with tube-and-coupler or frame scaffolding, Ringlock Scaffolding offers faster assembly, higher load-bearing capacity, and adaptability for complex structures. Its modular components allow vertical stacking, horizontal spans, and curved or irregular layouts. This makes it ideal for building facades, industrial plants, bridges, and large infrastructure projects.

Ringlock Scaffolding is highly durable and reusable. Components are treated with corrosion-resistant finishes, ensuring long-term service in various environments. Lightweight but strong, the system can be easily transported, repositioned, and reused across multiple projects, offering cost-efficiency.

Proper installation and inspection are critical for safety. Each connection must be secured at the rosette, load limits should be strictly followed, and platforms checked for stability. When used correctly, Ringlock Scaffolding provides safe, efficient, and versatile access solutions, improving productivity and structural safety on construction sites.

Visual content is essential for demonstrating the structure, installation, and applications of Ringlock Scaffolding. High-quality images help contractors, engineers, and site supervisors understand assembly, safety features, and versatility.

Common image types include:

Product Overview: Fully assembled scaffolding highlighting vertical standards, horizontal ledgers, diagonal braces, and rosette connections.

Detail Images: Close-ups of the rosette connections, locking pins, tube ends, and anti-slip platforms.

Modular Assembly: Illustrating vertical stacking, horizontal spans, and complex configurations such as curved or multi-level setups.

On-Site Applications: Photos of scaffolding used in high-rise buildings, industrial plants, bridge maintenance, and large-scale infrastructure projects.

Accessories Demonstration: Base jacks, ladders, guardrails, stabilizers, and toe boards in use.

Installation Process: Step-by-step visuals showing vertical standard placement, ledger and brace connection, platform installation, and final inspection.

These images are widely used in catalogs, technical manuals, online product listings, and training materials. They provide practical guidance for safe installation, highlight structural strength, and demonstrate the system’s versatility in different project scenarios.

By combining technical specifications with high-quality visuals, engineers, contractors, and project managers can confidently select Ringlock Scaffolding for efficient, safe, and reliable working platforms on construction sites of any scale.