Scaffolding Tubes are essential components of modern scaffolding systems, valued for their strength, durability, and versatility. One of their primary advantages is the ability to carry heavy vertical and horizontal loads, making them suitable for both residential and large-scale commercial construction projects. These tubes form the backbone of scaffolding frameworks, ensuring safe and stable working platforms.

Another key selling point is standardized dimensions and high-quality steel construction. Scaffolding tubes are manufactured with precise outer and inner diameters, consistent wall thickness, and smooth surfaces, allowing easy integration with clamps, couplers, and other scaffold accessories. This standardization ensures compatibility with international scaffolding systems, improving installation efficiency.

Safety and durability are also central features. Scaffolding tubes can withstand high loads, resist bending or deformation, and maintain structural integrity under dynamic site conditions. Optional surface treatments, such as hot-dip galvanization or painted finishes, provide excellent corrosion resistance, extending the tube’s lifespan even in harsh environmental conditions.

Ease of transport and handling further adds to their utility. Lightweight relative to their strength, scaffolding tubes can be quickly moved and installed, reducing labor effort and improving site productivity. Their reusable nature provides cost-effectiveness across multiple construction projects.

Overall, scaffolding tubes combine strength, precision, safety, and versatility, making them an indispensable element in forming secure and efficient scaffolding systems for any construction environment.

Scaffolding Tubes are manufactured to meet stringent quality standards for construction applications. Typical technical parameters include:

Material: High-strength carbon steel or galvanized steel

Outer Diameter: Commonly 48.3 mm (standard), other sizes available

Wall Thickness: 3.2 mm or customized according to load requirements

Length: Standard lengths 6 m, 7.2 m, 12 m (custom sizes available)

Load Capacity: Designed to handle vertical and horizontal loads per scaffolding standards

Surface Treatment: Painted or hot-dip galvanized for corrosion resistance

Compliance: Manufactured according to EN 39, BS 1139, or other international scaffolding standards

Usage: Vertical standards, horizontal ledgers, bracing, and structural support

Scaffolding tubes are versatile and can be used for both temporary and semi-permanent scaffolding setups. Their precise dimensions ensure secure connections with clamps, couplers, and other scaffold accessories, forming stable frameworks for workers and materials.

Regular inspection for corrosion, cracks, or deformation is recommended to maintain safety and service life. Proper handling and storage also prevent damage and ensure that tubes retain their load-bearing performance over multiple construction cycles.

Scaffolding Tubes are the backbone of scaffolding systems, forming the vertical, horizontal, and diagonal elements of temporary frameworks used in construction and maintenance. Their primary function is to provide structural integrity and safe load distribution for elevated platforms.

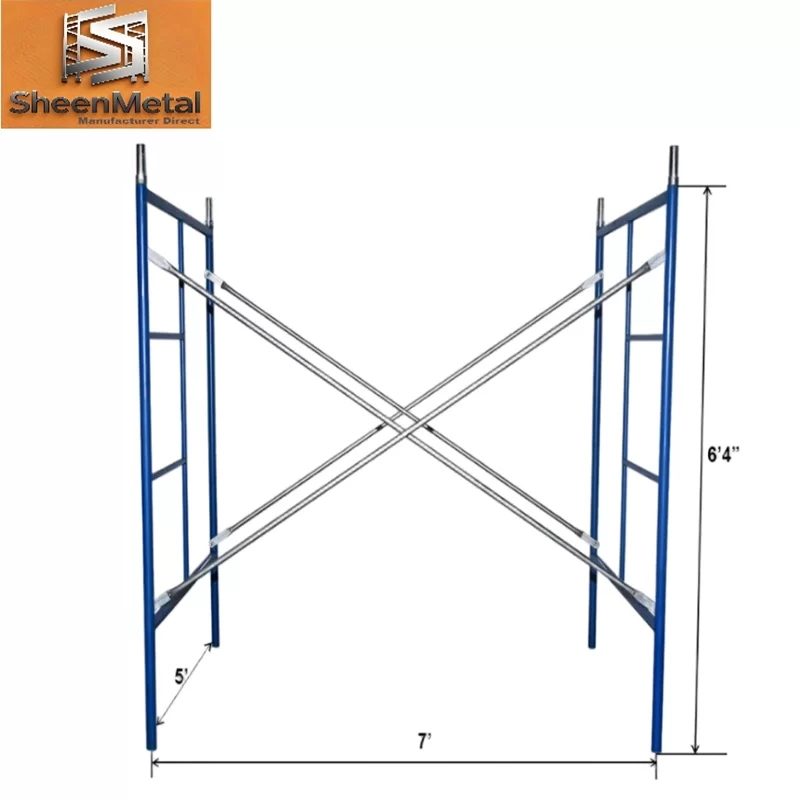

The working principle is based on combining multiple tubes with clamps, couplers, or accessories to form a secure framework. Vertical tubes (standards) carry vertical loads, while horizontal tubes (ledgers) and diagonal tubes (braces) provide lateral stability and prevent swaying. Together, they form rigid scaffolding capable of supporting workers, materials, and equipment.

Compared with traditional timber or makeshift supports, steel scaffolding tubes offer superior strength, uniformity, and reliability. They can be easily cut to size, connected with standardized couplers, and reused across multiple projects, reducing material waste and construction costs.

Applications of scaffolding tubes are extensive, including building construction, bridge maintenance, industrial facilities, painting, and inspection work. They are suitable for both modular frame scaffolding and tube-and-coupler scaffolding systems.

For safe usage, scaffolding tubes must be installed on level surfaces, securely connected with clamps or couplers, and used within their load capacity. Routine inspection for corrosion, deformation, or damage is essential. When properly maintained and used, scaffolding tubes provide a durable, safe, and cost-effective solution for elevated work platforms and temporary construction support structures.

Visual content is essential to demonstrate the structure, assembly, and practical application of scaffolding tubes. High-quality images help engineers, contractors, and site managers understand their role in forming secure scaffolding systems.

Common image types include:

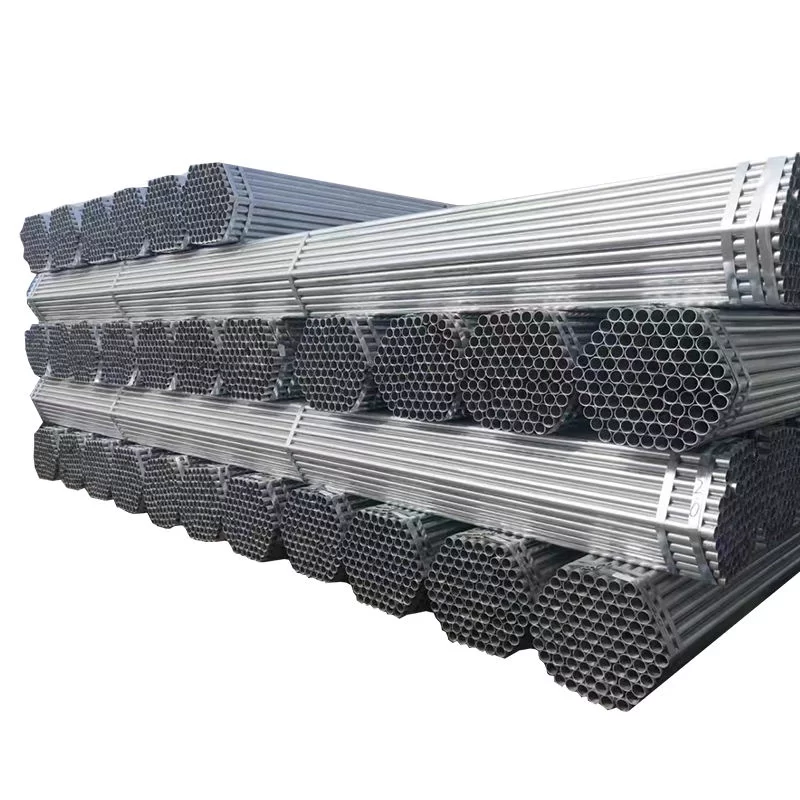

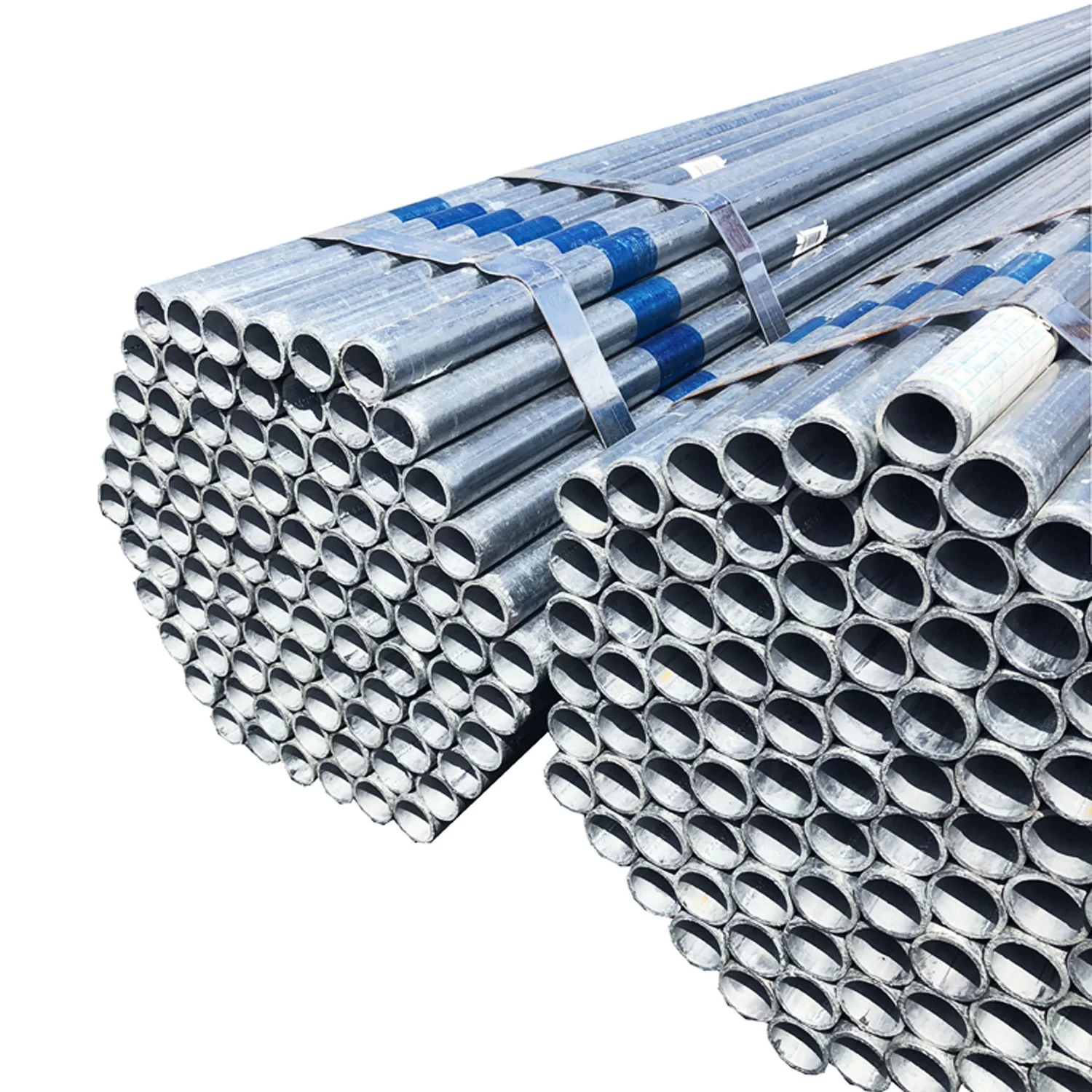

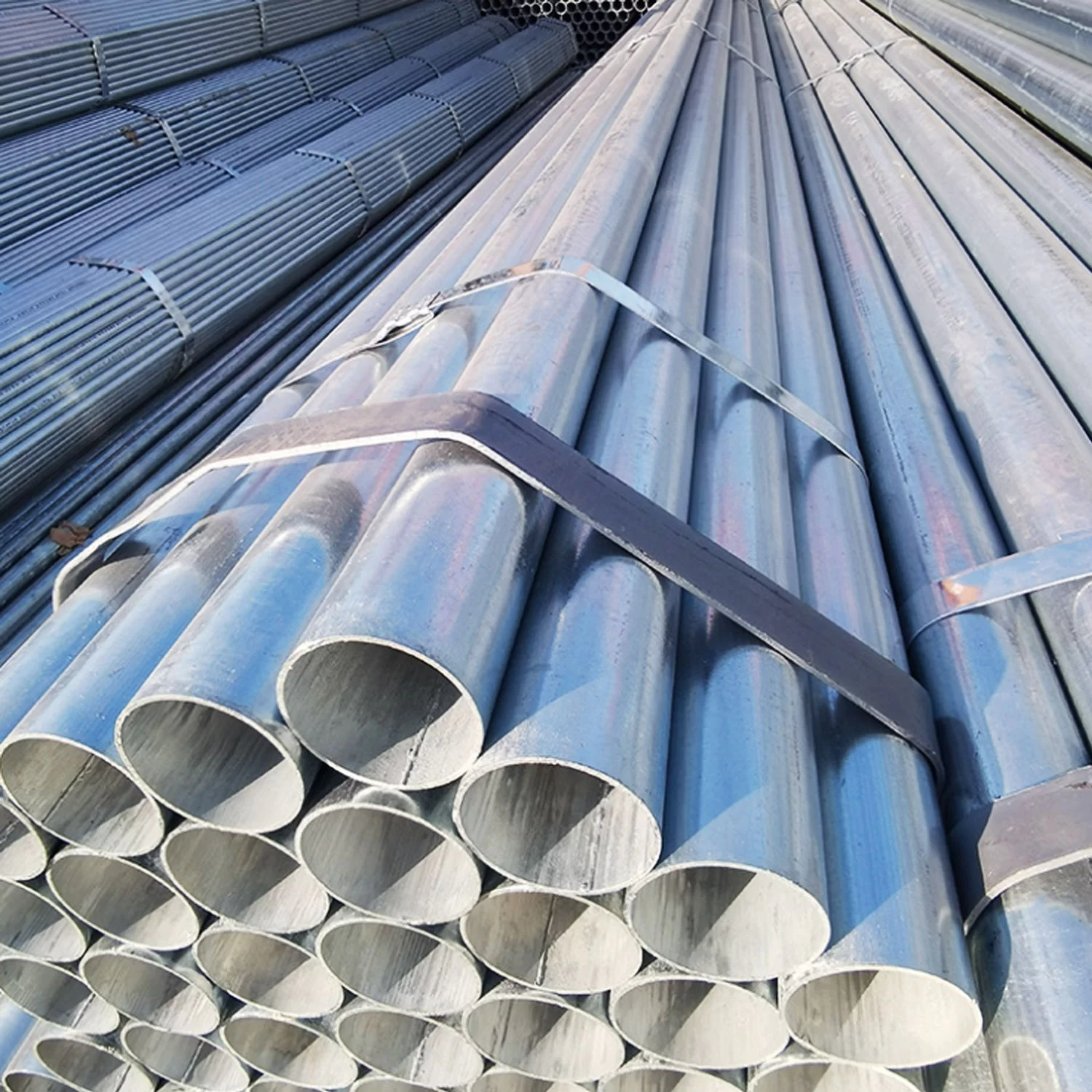

Product Overview: Individual scaffolding tubes, showing smooth surfaces, uniform diameter, and wall thickness.

Detail Images: Close-ups of galvanized coating, painted finishes, and tube ends.

Assembly Examples: Tubes connected with clamps or couplers to form vertical and horizontal scaffolding frameworks.

On-Site Applications: Scaffolding tubes used in building construction, façade installation, industrial maintenance, and bridge repair.

Structural Components: Demonstrating vertical standards, horizontal ledgers, and diagonal braces in modular or tube-and-coupler systems.

Installation Process: Step-by-step visuals showing tubes being positioned, connected, and secured to create stable scaffolding.

These images are commonly used in catalogs, technical manuals, training materials, and online product pages. They provide practical guidance for safe installation, illustrate structural versatility, and highlight the scaffolding tube’s quality and durability.

By combining technical specifications with high-quality visuals, contractors and engineers can confidently select scaffolding tubes for safe, efficient, and reliable temporary work platforms on construction sites.