The South Asia Frame Scaffolding is engineered to deliver maximum safety, flexibility, and efficiency for modern construction projects. One of its primary advantages is quick assembly and modular design. With pre-fabricated frames, cross braces, and platforms, it can be assembled rapidly without requiring complex tools or specialized labor. This significantly reduces installation time and overall project costs.

Safety and stability are core features. The scaffolding frames are made from high-strength steel and designed to distribute loads evenly across platforms. Anti-slip platforms and secure locking mechanisms provide additional protection, ensuring a safe working environment for personnel performing tasks at height. The design meets international safety standards, making it suitable for professional construction applications.

Another key selling point is its versatility and adaptability. The modular frame system allows scaffolds to be configured in various heights and widths, making it ideal for indoor and outdoor applications. It is suitable for tasks such as building maintenance, painting, façade installation, and industrial inspections. Optional accessories like guardrails, ladders, and stabilizers further enhance usability and safety.

The system is also durable and reusable. With painted or galvanized finishes, the scaffolding resists corrosion, wear, and harsh environmental conditions, making it cost-effective for multiple project cycles. Its lightweight yet strong structure ensures easy transportation and repositioning on-site.

Overall, South Asia Frame Scaffolding combines safety, efficiency, durability, and adaptability, making it a reliable choice for contractors, builders, and maintenance teams seeking a high-performance scaffolding solution.

The South Asia Frame Scaffolding is manufactured to strict quality standards, ensuring structural reliability and safety in a wide range of construction applications. Typical technical parameters include:

Material: High-strength carbon steel or galvanized steel

Frame Dimensions: Commonly 0.9 m × 2.0 m, 0.9 m × 1.5 m (custom sizes available)

Load Capacity: Typically 200–250 kg per platform level

Height Range: Modular configuration allows heights up to 20 m or more

Platform Material: Anti-slip steel or aluminum decking

Cross Braces: High-strength steel tubes with locking pins

Surface Treatment: Painted or hot-dip galvanized for corrosion resistance

Accessories: Guardrails, ladders, stabilizers, toe boards

Assembly Method: Modular frame and brace system with pin connections

The modular design allows the scaffold to be customized according to project requirements. Frames can be stacked vertically, and horizontal bracing provides lateral stability. Base plates or adjustable screw jacks ensure safe and level installation on uneven ground.

South Asia Frame Scaffolding can be integrated with other formwork and scaffolding systems, providing flexibility for complex construction sites. Its robust construction ensures long-term performance and reliability under repeated use, while its modularity allows efficient storage and transport.

Regular inspection, proper assembly, and adherence to load limits are essential to maintain safety and durability. With these measures, the scaffold system provides an efficient, safe, and cost-effective solution for construction projects of all scales.

Frame scaffolding is a widely used modular support and access system in construction. The South Asia Frame Scaffolding is designed to meet regional construction needs, including high-rise buildings, industrial facilities, and infrastructure projects. Its modular design allows fast assembly and disassembly, saving both labor and time on-site.

The scaffolding works by creating a stable vertical and horizontal structure through interconnecting frames and cross braces. Once assembled, it provides a secure platform for workers, tools, and materials. Anti-slip platforms and guardrails enhance safety, while the steel frame ensures load-bearing stability.

Compared with traditional tube-and-coupler scaffolding, frame scaffolding offers significant advantages. It reduces assembly complexity, provides uniform load distribution, and allows faster erection. Its standardized components ensure compatibility and safe connections, while its modularity allows for multiple configurations depending on height, span, and site conditions.

Frame scaffolding is widely used for construction, renovation, façade work, painting, maintenance, and industrial inspections. Its lightweight yet strong design ensures it can be easily repositioned, while durable finishes protect it against corrosion, moisture, and environmental wear.

Proper installation and safety procedures are essential. Frames must be securely braced, leveled, and anchored to prevent tipping. Load limits should be strictly followed to ensure worker safety and scaffold longevity. When used correctly, South Asia Frame Scaffolding offers an efficient, reliable, and safe solution for working at height.

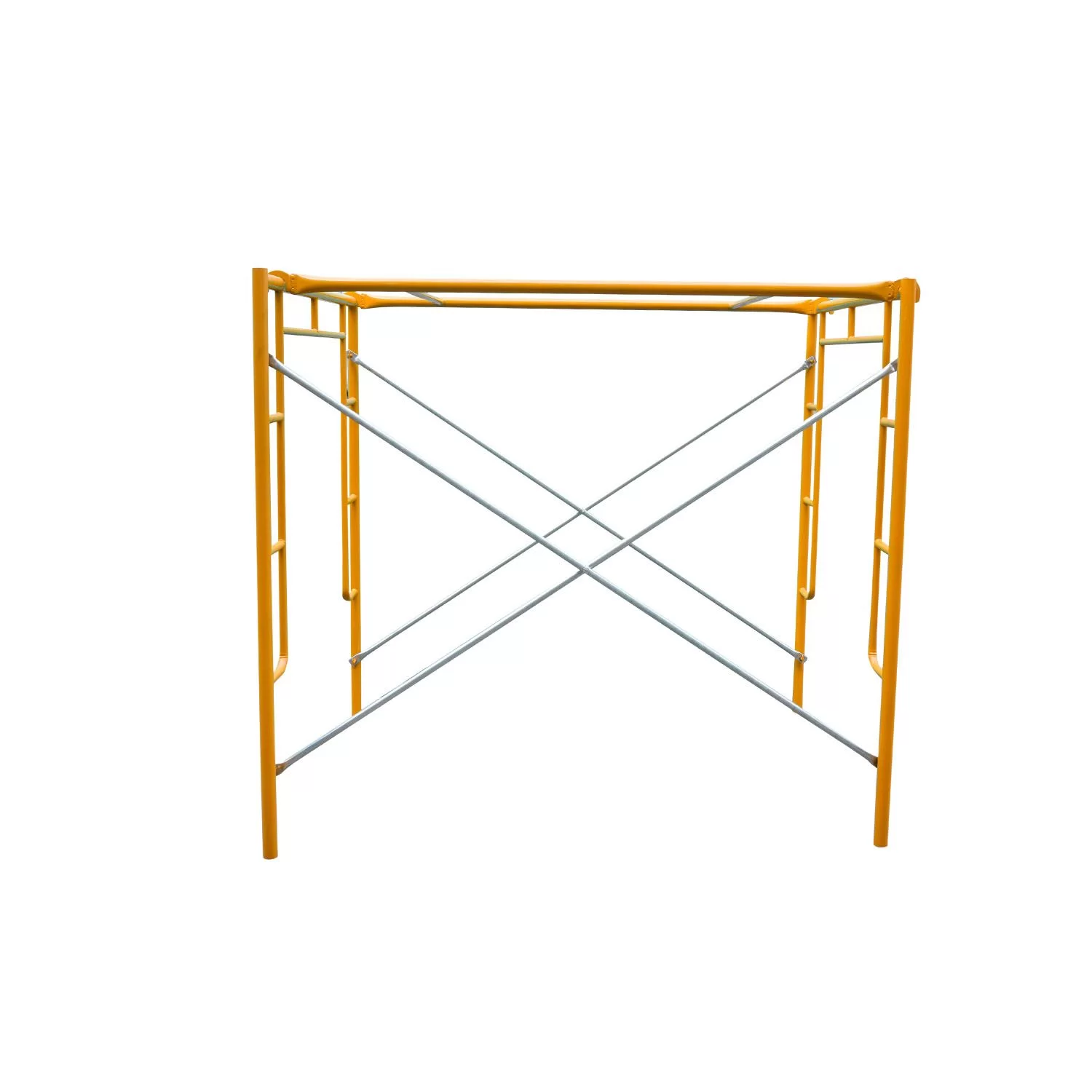

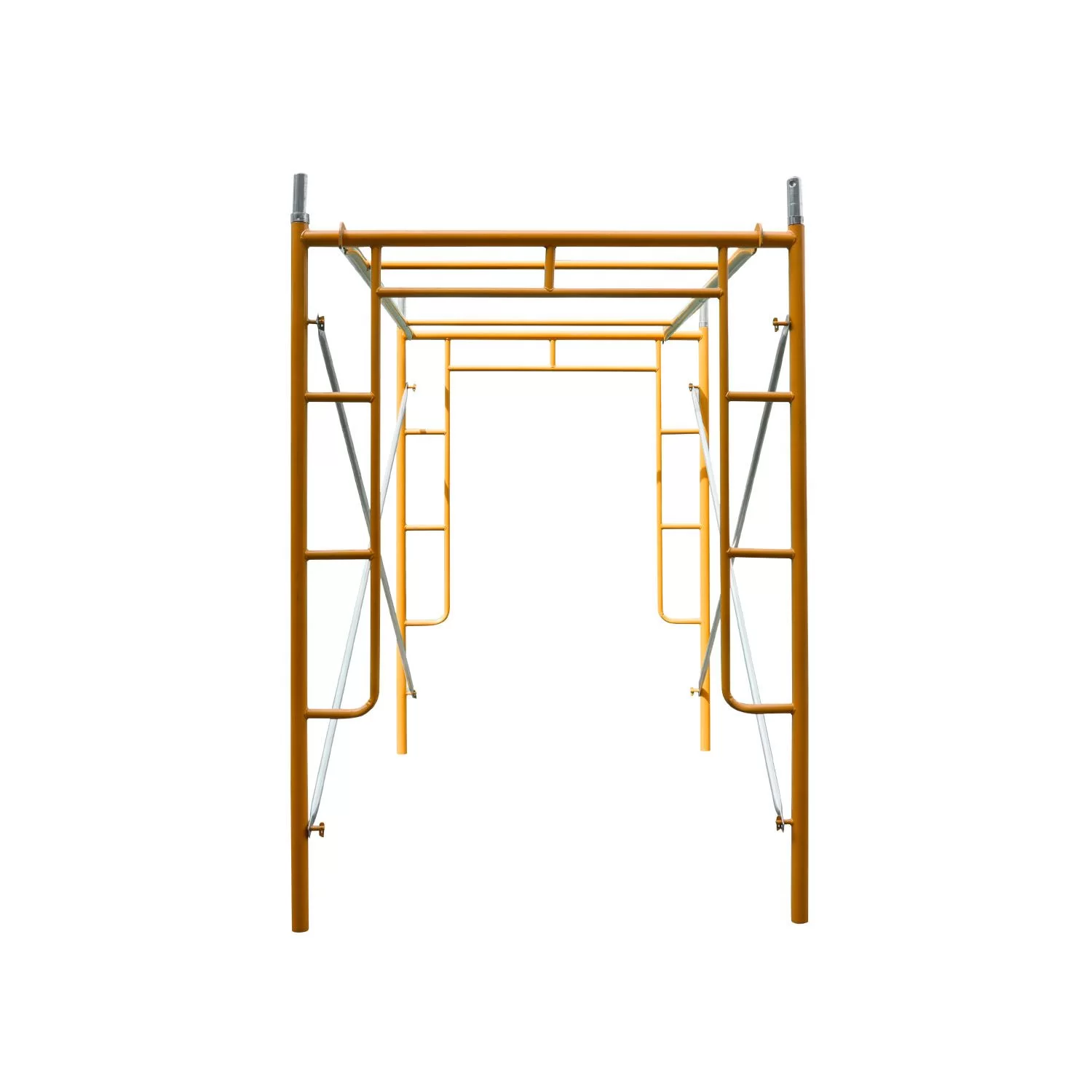

Visual presentation is crucial for demonstrating the structure, assembly, and practical use of South Asia Frame Scaffolding. Clear images help contractors and site managers quickly understand installation methods, safety features, and adaptability.

Common image types include:

Product Overview: Showing assembled scaffolding frames with platforms, braces, and guardrails.

Detail Images: Close-ups of frame connections, locking pins, base plates, and anti-slip decking.

Modular Assembly: Images showing vertical stacking, horizontal spans, and adjustable heights.

On-Site Applications: Photos of scaffolding used in building construction, façade work, industrial maintenance, and painting.

Accessories Demonstration: Guardrails, ladders, stabilizers, and toe boards in use.

Installation Process: Step-by-step visuals illustrating frame setup, bracing, and platform installation.

These images are used in catalogs, technical manuals, online product pages, and training materials. They provide practical guidance for safe use, demonstrate the scaffolding’s versatility, and highlight the robustness and quality of the system.

By combining detailed visuals with technical and safety information, contractors and engineers can evaluate the South Asia Frame Scaffolding for their projects, ensuring safe, efficient, and reliable working platforms at all construction sites.