3 Layer Plywood Formwork provides a combination of strength, reusability, and high-quality concrete finishing. One of its main advantages is the laminated three-layer construction, which offers enhanced load-bearing capacity while reducing bending, warping, or cracking during use. This ensures a stable formwork structure capable of withstanding heavy concrete loads and construction stress.

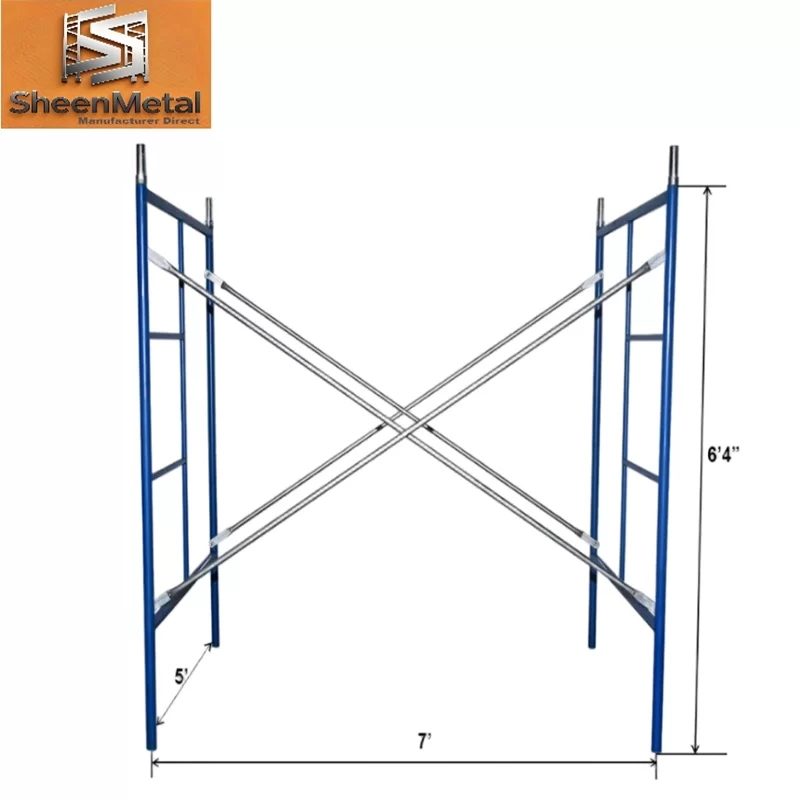

Ease of assembly is another key benefit. Panels are lightweight yet strong, allowing faster installation, handling, and adjustment compared to traditional timber formwork. The system is compatible with standard scaffolding supports, U Head Jacks, and base jacks, enabling precise leveling and alignment. Modular panels allow efficient construction of walls, columns, beams, and slabs of various dimensions.

Durability and reusability are essential selling points. The plywood is treated and laminated with high-quality adhesives, making it moisture-resistant and long-lasting, suitable for multiple construction cycles. Its smooth surface produces high-quality concrete finishes, reducing post-pour finishing work and labor costs. Some panels come with a phenolic film overlay, further enhancing durability, chemical resistance, and ease of cleaning.

The system is environmentally friendly due to reusability, reducing the need for cutting timber on-site and minimizing construction waste. Accessories such as corner panels, tie rods, wedges, and clamps increase versatility and adaptability to complex structures.

Overall, 3 Layer Plywood Formwork combines strength, stability, efficiency, and sustainability, making it an ideal choice for engineers, contractors, and site managers seeking reliable, high-performance formwork for various concrete structures.

3 Layer Plywood Formwork is manufactured according to international standards for strength, dimensional stability, and durability. Typical technical parameters include:

Material: Three-layer laminated plywood with phenolic resin adhesive

Panel Size: 1200 mm × 2400 mm, 1200 mm × 600 mm, or custom sizes

Panel Thickness: 18 mm, 21 mm, 25 mm, or as required for load capacity

Load Capacity: Supports 40–60 kN/m² depending on panel size and support span

Surface: Smooth phenolic film or natural plywood finish for high-quality concrete

Durability: Moisture-resistant, impact-resistant, and reusable over multiple cycles

Accessories: Corner panels, tie rods, wedges, clamps, and support frames

Compatibility: Compatible with U Head Jacks, base jacks, scaffolding, and other modular support systems

Application: Wall formwork, slab formwork, column formwork, beam formwork

The three-layer construction enhances bending resistance and dimensional stability, ensuring a consistent concrete surface finish and reliable structural support. Panels can be joined using standard clamps and tie rods to achieve larger surfaces and complex geometries. Proper bracing and alignment are essential to maintain structural integrity during concrete pouring.

Regular inspection of panels for warping, delamination, or surface damage is necessary to maintain safety and performance. Proper cleaning and storage extend the service life and ensure consistent results across multiple uses.

3 Layer Plywood Formwork is a widely used modular formwork solution in modern construction due to its strength, durability, and high-quality finishing capabilities. The system consists of laminated plywood panels bonded with strong adhesives to resist bending, warping, and moisture penetration, ensuring reliable performance over multiple uses.

The formwork functions by creating a temporary mold for concrete, supporting the load until the concrete achieves sufficient strength. Panels are supported on U Head Jacks, base jacks, scaffolding, or other modular support systems. Tie rods, wedges, and clamps ensure alignment and stability, while corner panels enable construction of vertical and horizontal junctions with precise angles.

Compared to traditional timber or metal formwork, 3 Layer Plywood Formwork is lighter, easier to handle, and faster to install, reducing labor costs and construction time. Its phenolic or smooth plywood surface provides high-quality concrete finishes, minimizing post-casting finishing work. This improves both aesthetics and structural quality.

Durable and reusable, the panels are ideal for residential, commercial, and industrial projects, including high-rise buildings, bridges, tunnels, and precast elements. Proper maintenance, including cleaning, inspection, and careful storage, ensures multiple usage cycles and long-term cost efficiency.

Safety is enhanced through strong, stable panels and secure fixing with tie rods, clamps, and jacks. By combining lightweight handling, high load-bearing capacity, and smooth surface finish, 3 Layer Plywood Formwork offers efficient, reliable, and sustainable solutions for a variety of concrete construction applications.

Visual content is essential for demonstrating the structure, installation, and applications of 3 Layer Plywood Formwork. High-quality images help engineers, contractors, and site supervisors understand assembly methods, compatibility, and finished results.

Common image types include:

Product Overview: Individual three-layer plywood panels showing thickness, lamination, and surface finish

Detail Images: Close-ups of phenolic coating, edges, corners, and surface smoothness

Installation Examples: Panels assembled for walls, slabs, columns, or beam formwork with tie rods and clamps

On-Site Applications: Formwork in residential, commercial, and industrial construction sites, including high-rise buildings, bridges, and tunnels

Assembly Demonstration: Step-by-step visuals showing placement on U Head Jacks, base jacks, and scaffolding supports

Concrete Pouring: Images showing smooth concrete surfaces after formwork removal and proper alignment of panels

These images are widely used in catalogs, technical manuals, online product listings, and training materials. They provide practical guidance for proper installation, highlight durability and load-bearing performance, and demonstrate versatility for multiple concrete forming applications.

Combining technical specifications with high-quality visuals ensures that engineers, contractors, and project managers can confidently select 3 Layer Plywood Formwork for durable, efficient, and high-quality concrete construction projects.